Specifications:

| Materials | Optical grade germanium single crystals | Diameter Range | ~300mm |

| Diameter Tolerance | -0.01/-0.03mm | Thickness Tolerance | +/-0.03mm |

| Surface Quality | 60/40 S/D | Fringes (N) | 3 |

| Irregularity (delta N) | 1 | Centration | 3' |

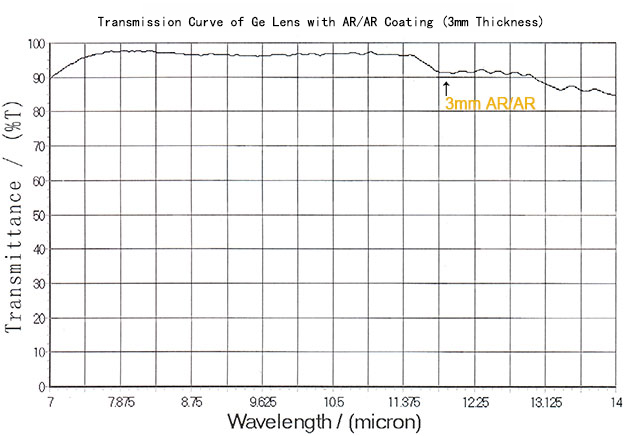

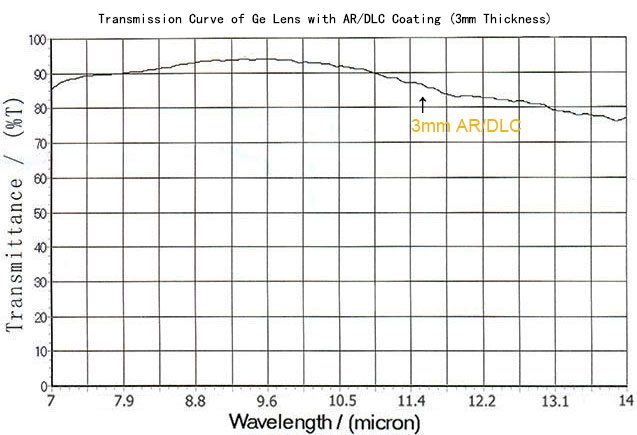

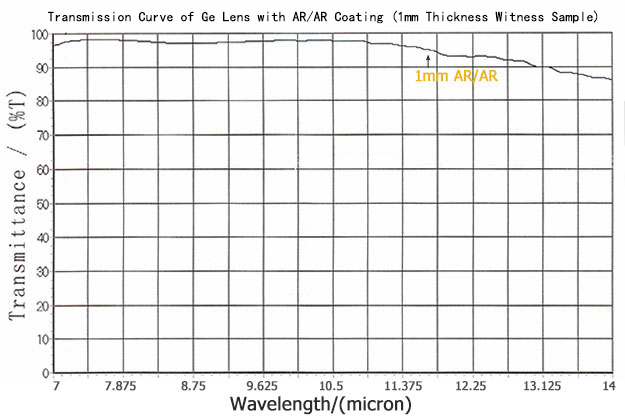

| Chamfer | 0.1-0.3mmx45 degree | Coatings | AR/AR@7-14micro DLC/AR@7-14micro BBAR/BBAR@3-12 micro See coating curves below |

Physical and Optical Properties:

| Transmission Range | 1.8 to 23 μm | Refractive Index | 4.0026 at 11 μm |

| Reflection Loss | 53% at 11 μm (2 surfaces) | Absorption Coefficient | <0.027 cm-1@ 10.6 μm |

| Reststrahlen Peak | n/a | dn/dT | 396 x 10-6 /°C |

| dn/dμ = 0 | Almost constant | Density | 5.33 g/cc |

| Melting Point | 936 °C | Thermal Conductivity | 58.61 W m-1 K-1 at 293K |

| Thermal Expansion | 6.1 x 10-6/°C at 298K | Hardness | Knoop 780 |

| Specific Heat Capacity | 310 J Kg-1 K-1 | Dielectric Constant | 16.6 at 9.37 GHz at 300K |

| Youngs Modulus (E) | 102.7 GPa | Shear Modulus (G) | 67 GPa |

| Bulk Modulus (K) | 77.2 GPa | Elastic Coefficients | C11=129; C12=48.3; C44=67.1 |

| Apparent Elastic Limit | 89.6 MPa (13000 psi) | Poisson Ratio | 0.28 |

| Solubility | Insoluble in water | Molecular Weight | 72.59 |

| Class/Structure | Cubic Diamond, Fd3m |

Germanium lenses (Ge lenses) are often incorporated into IR imaging systems operating from 2µm to 16 µm, covering the LWIR (8-12μm) and MWIR (3-5μm) spectral range with their broad transmission to the IR radiations and opacity to the UV and VIS wavelengths. Ge lens has the highest refractive index of common IR transmitters, which implies great light collection and bending strength. Ge lens exhibits slight chromatic aberration due to low optical dispersion, meaning minimal distortion and spreading of light, ensuring authentic transmission of the optical signals. Germanium has a Knoop Hardness of 780, this trait contributes to the rugged nature of Germanium Lenses. Germanium can be Diamond or DLC coated to be utilized as the front optics in the lens group with surpassing toughness to withstand demanding environments. Caution should be taken for high-temperature conditions where the Ge will become opaque to IR wavelengths as the temperature rises. In addition, its relatively high density should be considered where weight is an issue.

The optical transmission rate of Germanium is over 45% between 2-14μm at temperatures up to 45⁰C, with optimal transmission spectrum residing between 2-12μm, and after the anti-reflection coating process, average transmission could be leveraged to above 95%. However, the transmission of Ge lenses starts to degrade at 100⁰C, then plummets above 200⁰C. Exposure to higher temperatures can lead to catastrophic failure in the material so Germanium is unsuitable for use in high-temperature conditions.

Hangzhou Shalom EO suppliers a series of custom Germanium Lenses including plano-convex, Plano-concave, double convex, double concave, and meniscus Ge lenses, with spherical and aspherical lens surfaces. Due to the large refractive index of Ge, AR coatings are needed to enhance its transmission. Coating Options encompass Anti-reflection (AR), Broad Band AR (BBAR), and Diamond (DLC) coatings. The shapes, dimensions (diameters, up to 300mm), and coatings could all be tailored upon request. Besides the conventional spherical surface lenses, Hangzhou Shalom EO also provides aspherical surface lenses made by the SPDT (Single Point Diamond Turning) technique.

Plano-convex Germanium Lenses have a positive focal length and are designed for light collimation and focusing. Plano-concave Ge Lenses are for expanding collimated lights or diverging light and could be incorporated into beam expanders. Double Convex and Double Concave Ge Lenses have two convex or concave planes. Meniscus Ge Lenses have one concave front and one convex front and are excellent for reducing spherical aberrations. Aspheric Ge Lenses have a more complex profile and the advantage of eliminating spherical aberrations, therefore a single aspheric lens can substitute multiple spherical lenses with the exemption of using lenses to correct spherical aberration. Hangzhou Shalom EO fabricates aspherical Ge lenses using the SPDT (Single Point Diamond Turning) technique, which is a manufacturing process in which a computer-controlled lathe uses a diamond tip to directly cut the desired profile.

Applications for Germanium Lenses:

Curves:

1. Transmission curve of Ge windows with no coating

.jpg)

2. Transmission Curve of Ge Lens with AR/AR Coating (1mm Thickness Witness Sample)

3. Transmission Curve of Ge Lens with AR/AR Coating (3mm Thickness)