This article is a basic introduction to Thermal Camera Lenses, which refers to the lens components used for infrared thermal imaging.

First of all, before understanding thermal camera lens, we must figure out what are thermal imager and thermal camera, and how do these two work? Object with a surface temperature higher than the absolute zero (-273°C) emits infrared magnetic radiations (that is, the radiations with wavelengths beyond 700nm, but above 1000 microns) outward. Unlike a visible camera which produces images by capturing visible light, an infrared imager is a device that forms the image by detecting the temperature of the object. Because the thermal imaging system detects heat rather than light, it can be used 24/7, moreover, it is a piece of passive equipment, and there is no extra radiation, so it does not expose the user’s location.

The infrared spectrum can be divided into five categories according to different wavelength ranges: Near Infrared (NIR), wavelength range 0.75 microns-1.4 microns; Short Wave Infrared (SWIR), wavelength range 1.4 microns-3 microns; mid-infrared, wavelength range 3 microns-5 microns; Long Wave Infrared, wavelength range 8 microns-12 microns; and far-infrared, which ranges from 15 microns-1000 microns. Among them, The MWR and LWIR spectral regions are the two major wavelength ranges for thermal imaging. MWIR and LWIR radiation could

penetrate the atmosphere and produce the images by detecting the temperature difference of the objects, helping us to scout the environments better in fogged weather or at night.

Figure 1. This picture exhibits Shalom EO’s Thermal Imaging Lenses as an example

To be more specific about the working principle, a thermal imager or camera uses optics to focus the infrared radiation from the objects in the scene onto an infrared detector, and then the digital data from each detector element are converted into a standard video format that can be viewed on a standard video monitor or recorded on a videotape.

The detectors inside the thermal imagers are divided into two categories: photon detectors and thermal detectors. A Photon detector produces a direct electrical effect after absorbing infrared radiations, while a thermal detector produces a temperature change after absorbing the infrared waves, and generating an electrical effect. The material properties of the detectors affect how temperature changes induce the electrical effect.

In comparative terms, Photon detectors are more sensitive. However, heating up makes photon detectors less sensitive, so to remain sensitive, photon detectors must be cooled to lower temperatures. The commonly used coolant is Stirling or liquid nitrogen.

Thermal detectors are generally not as sensitive as photon detectors but perform well enough at room temperature. One advantage is that cryogenic cooling is not required so cost could be saved. For the most part, uncooled infrared FPA detectors/sensors are desigend to match with Long Wave Infrared (LWIR) thermal imaging camera lenses operating at 8-12 micro.

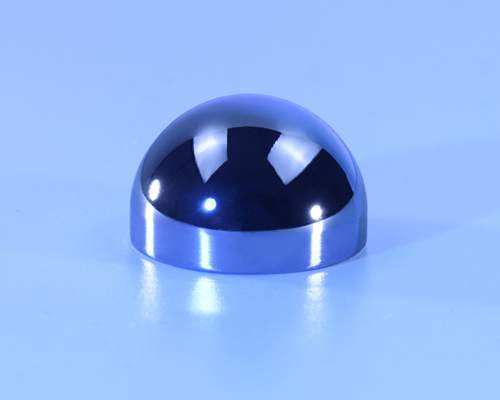

Therefore when designing and manufacturing infrared camera lenses, materials different from that of the visible lenses are chosen. The material should be transparent to the infrared wavelength range of interest. For example, silicon might not be as a good choice as germanium when producing LWIR Thermal Camera Lenses since silicon is opaque to wavelengths above 7000nm. Apart from materials, it is important to weigh and balance other factors such as field of view, weight, dimension, and the focusing mechanisms of the infrared camera lenses as well.

Figure 2. A Single Infrared Silicon Lens from Shalom EO