| Code |

Wavelength |

Diameter |

Thickness |

Wavefront Distortion |

Parallelism |

Extinction Ratio |

Coating |

AOI |

Laser Damage Threshold |

Application |

Unit Price |

Delivery |

Cart |

| 21212-001 |

515nm |

12.7mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@515nm, Tp>99%@515nm; S2: Rp<0.2%@515nm |

45° |

>4J/cm2@1030nm, 200ps, 100Hz |

Ultrafast Ytterbium |

Inquire |

Inquire |

|

| 21212-002 |

515nm |

12.7mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@515nm, Tp>99%@515nm |

56° |

>4J/cm2@1030nm, 200ps, 100Hz |

Ultrafast Ytterbium |

Inquire |

Inquire |

|

| 21212-003 |

515nm |

25.4mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@515nm, Tp>99%@515nm; S2: Rp<0.2%@515nm |

45° |

>4J/cm2@1030nm, 200ps, 100Hz |

Ultrafast Ytterbium |

Inquire |

Inquire |

|

| 21212-004 |

515nm |

25.4mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@515nm, Tp>99%@515nm |

56° |

>4J/cm2@1030nm, 200ps, 100Hz |

Ultrafast Ytterbium |

Inquire |

Inquire |

|

| 21212-005 |

800nm |

12.7mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@800nm, Tp>99%@800nm; S2: Rp<0.2%@800nm |

45° |

>2J/cm2@800nm, 100ps, 100Hz |

Ultrafast Ti:Sapphire |

Inquire |

Inquire |

|

| 21212-006 |

800nm |

12.7mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@800nm, Tp>99%@800nm |

56° |

>2J/cm2@800nm, 100ps, 100Hz |

Ultrafast Ti:Sapphire |

Inquire |

Inquire |

|

| 21212-007 |

1030nm |

12.7mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@1030nm, Tp>99%@1030nm; S2: Rp<0.2%@1030nm |

45° |

>4J/cm2@1030nm, 200ps, 100Hz |

Ultrafast Ytterbium |

Inquire |

Inquire |

|

| 21212-008 |

1030nm |

12.7mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@1030nm, Tp>99%@1030nm |

56° |

>4J/cm2@1030nm, 200ps, 100Hz |

Ultrafast Ytterbium |

Inquire |

Inquire |

|

| 21212-009 |

1030nm |

25.4mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@1030nm, Tp>99%@1030nm; S2: Rp<0.2%@1030nm |

45° |

>4J/cm2@1030nm, 200ps, 100Hz |

Ultrafast Ytterbium |

Inquire |

Inquire |

|

| 21212-010 |

1030nm |

25.4mm |

3.0mm |

λ/10 |

<1 arcsec |

1000:1 |

S1: Rs>99.9%@1030nm, Tp>99%@1030nm |

56° |

>4J/cm2@1030nm, 200ps, 100Hz |

Ultrafast Ytterbium |

Inquire |

Inquire |

|

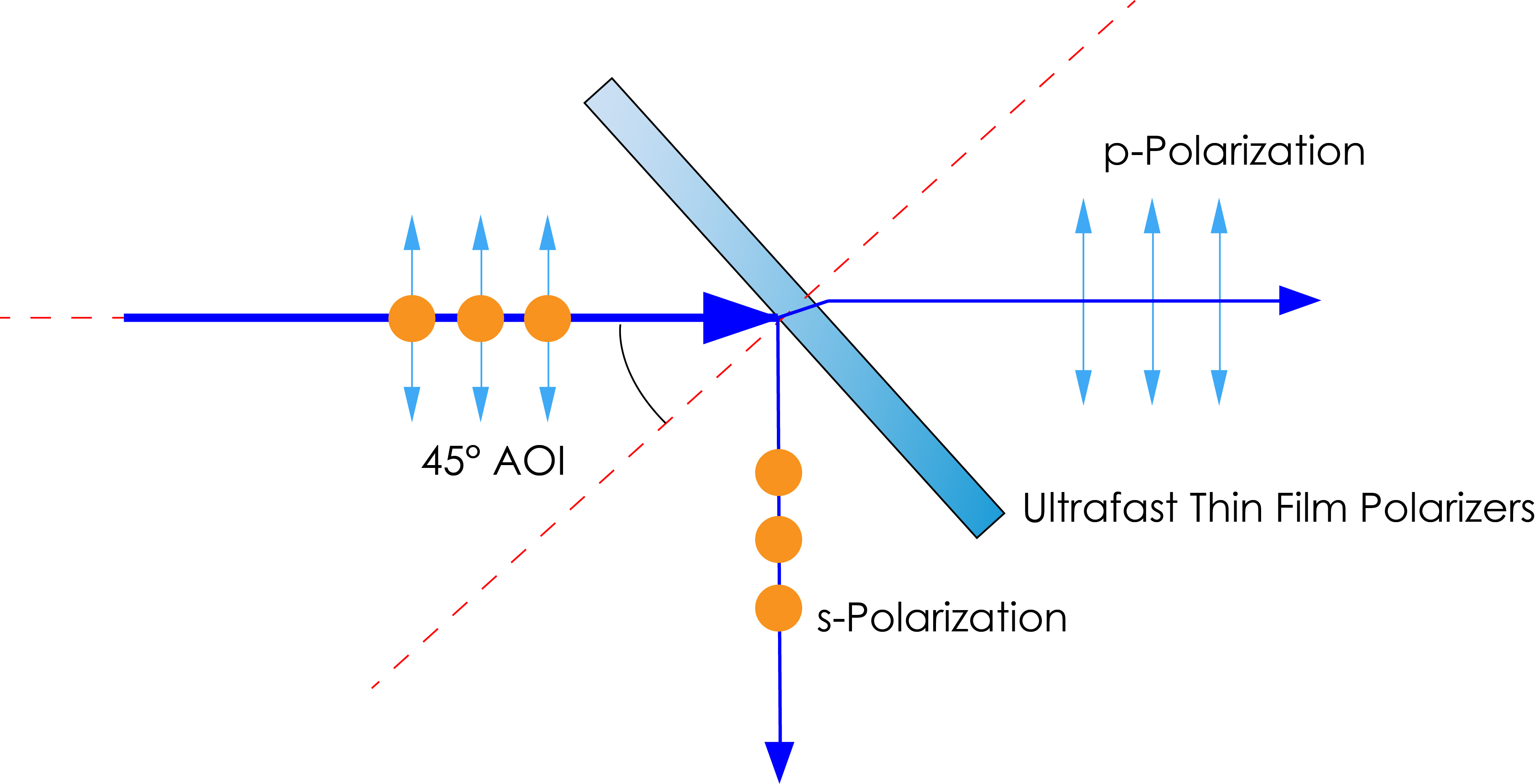

Thin film polarizers are optical components that separate the s polarization and the p polarization (transmit the p polarization component of light and reflect the s polarization ), thin film polarizers consist of dielectric coating deposited on optical glass substrates, unlike polaroizers (e.g. Glan-type polarizers) made of birefringent crystals that exploit the birefringent optical properties of the crystal material, the separate of polarization state is achieved using the interference effects in the design of the dielectric optical coating.

A thin film polarizer can either be plate type or cube shaped. Plate polarizers are constructed by a single plate substrate and a dielectric coating deposited on it that splits the s-polarization and the p-polarization. There are also polarizing cubes, which are constructed by two 45° prisms cemented together.

Shalom EO’s off-the-shelf and custom ultrafast thin film polarizers are thin plate polarizers made of fused silica glass substrates and IAD e-beam dielectric coating, optimized for ultrafast lasers (ultrafast Ti:sapphire lasers or ytterbium lasers). The IAD e-beam coating technique contributes to quick turnaround, cost effectiveness, durable, uniform thin film deposition, and high laser damage threshold of 4J/cm2@1030nm, 200ps, 100Hz or 2J/cm2@400nm, 100ps, 100ps. The ultrafast thin film polarizers are available in off-the-shelf and custom versions. The off-the-shelf femtosecond polarizers have a very thin thickness of 3mm. In terms of extinction ratio, our ultrafast thin film polarizers provide a high extinction ratio of 1000:1 and high polarization efficiencies.

Our standard thin film polarizers are manufactured using fused silica substrates shaped with a plano-plano geometric profile.

Regarding our standard thin film polarizers, two types of ultrafast thin film polarizers are available:

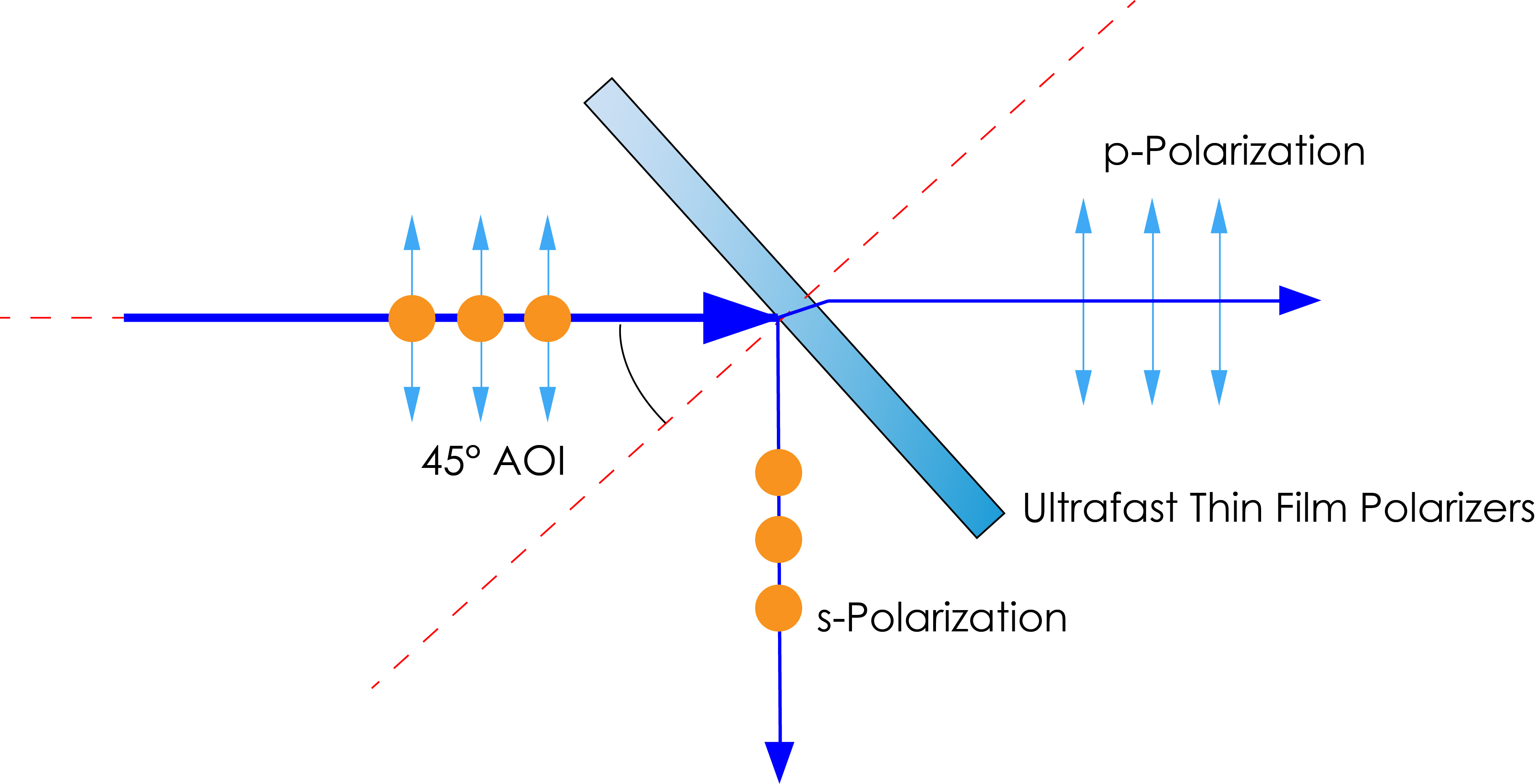

- Type 1 is designed to be used at a 45° angle of incidence. The front surfaces of these thin film polarizers are coated with reflectivity>99.9% for s-polarization and transmission>99% for the p-polarization, and the back surface is also coated to have a <0.2% reflectance for p-polarization.

Figure 1 is a diagram illustrating how a 45° AOI thin film polarizer separates the s-polarization and p-polarization

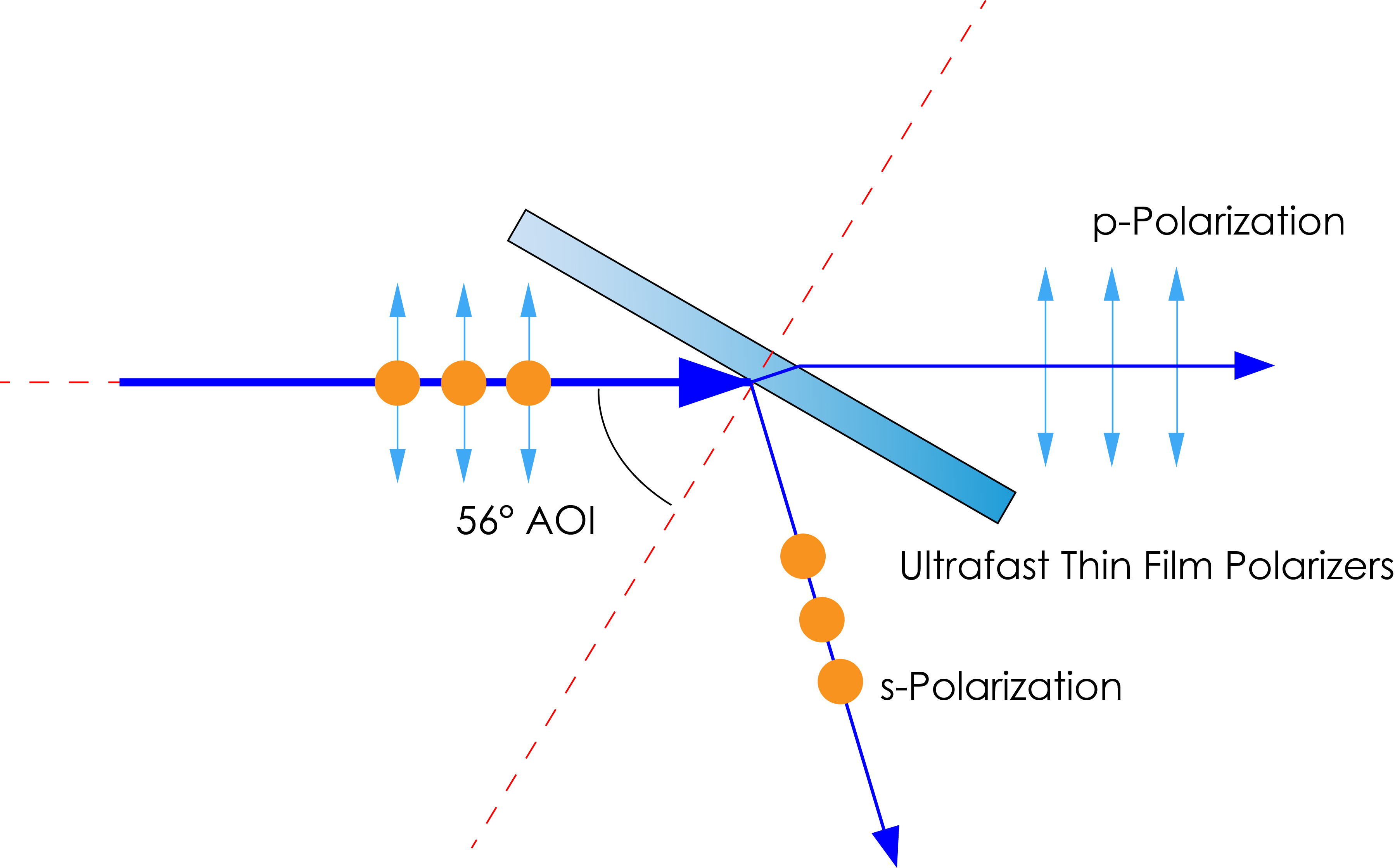

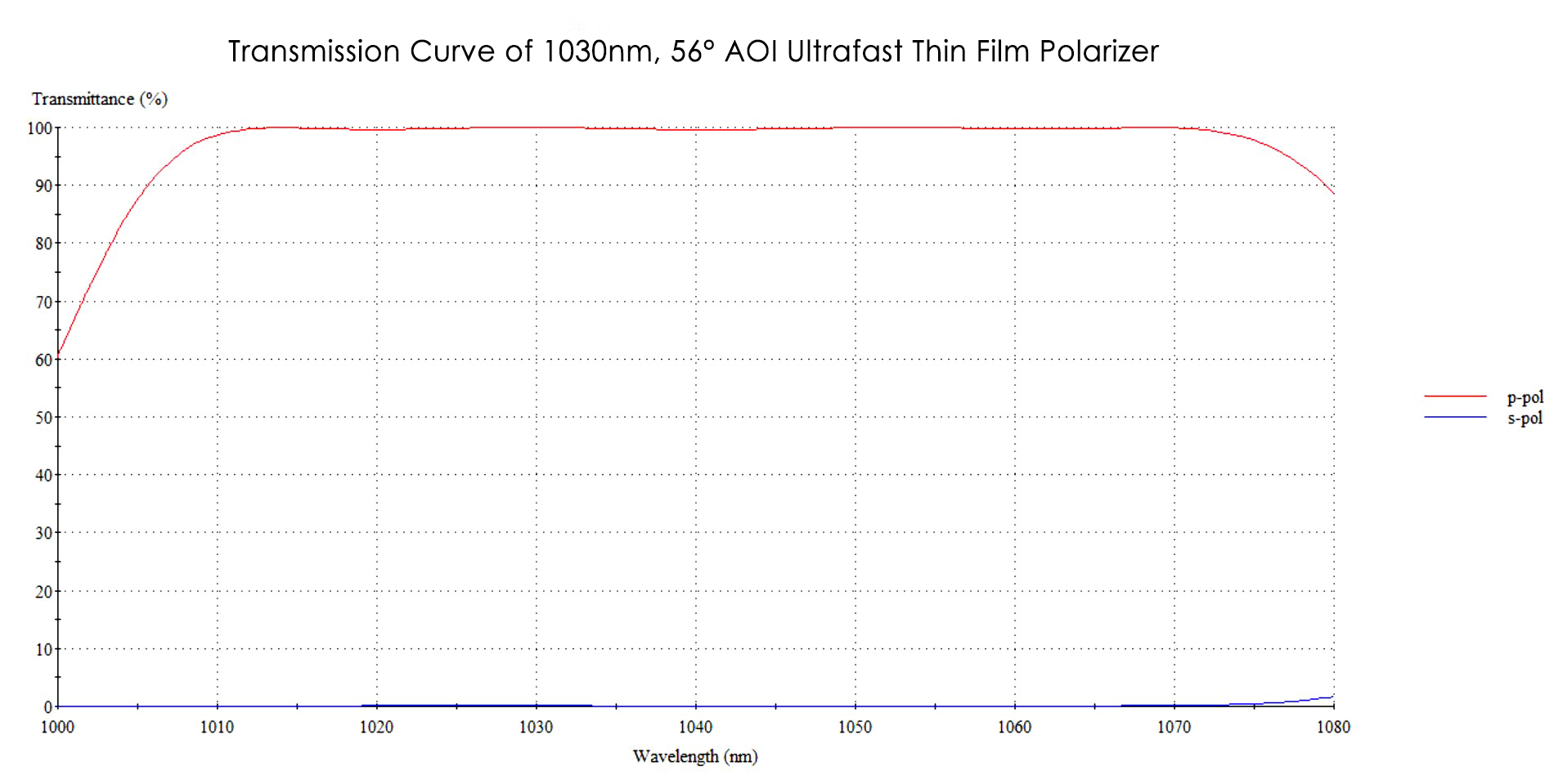

- Type 2 polarizer is designed to be used at the Brewster angle, which is a 56° angle of incidence as calculated from the refractive indices of glass and air. As the Brewster angle naturally separates the s and p polarization components at the second surface, surface 2 is uncoated.

Figure 2 is a diagram illustrating how a 56° AOI thin film polarizer separates the s-polarization and p-polarization

Important concepts about thin film polarizers that you should know:

1. Wavelength: The polarizer is tuned to work best at a specific wavelength or a narrow band of wavelengths. Shalom EO’s ultrafast thin film polarizers are engineered to obtain optimum results at certain laser wavelengths.

2. Angle of incidence (AOI).

Specifications:

| Type | Plano-plano Plate Polarizer | Substrate Material | Fused Silica |

| Wavefront Distortion | λ/10 (PV)@633nm | Parallelism | <1 arcsec |

| Clear Aperture | >90% | Extinction Ratio | 1000:1 |

| Chamfer | 0.3mm×45° | Surface Quality (S/D) | 20/10 |

Curves:

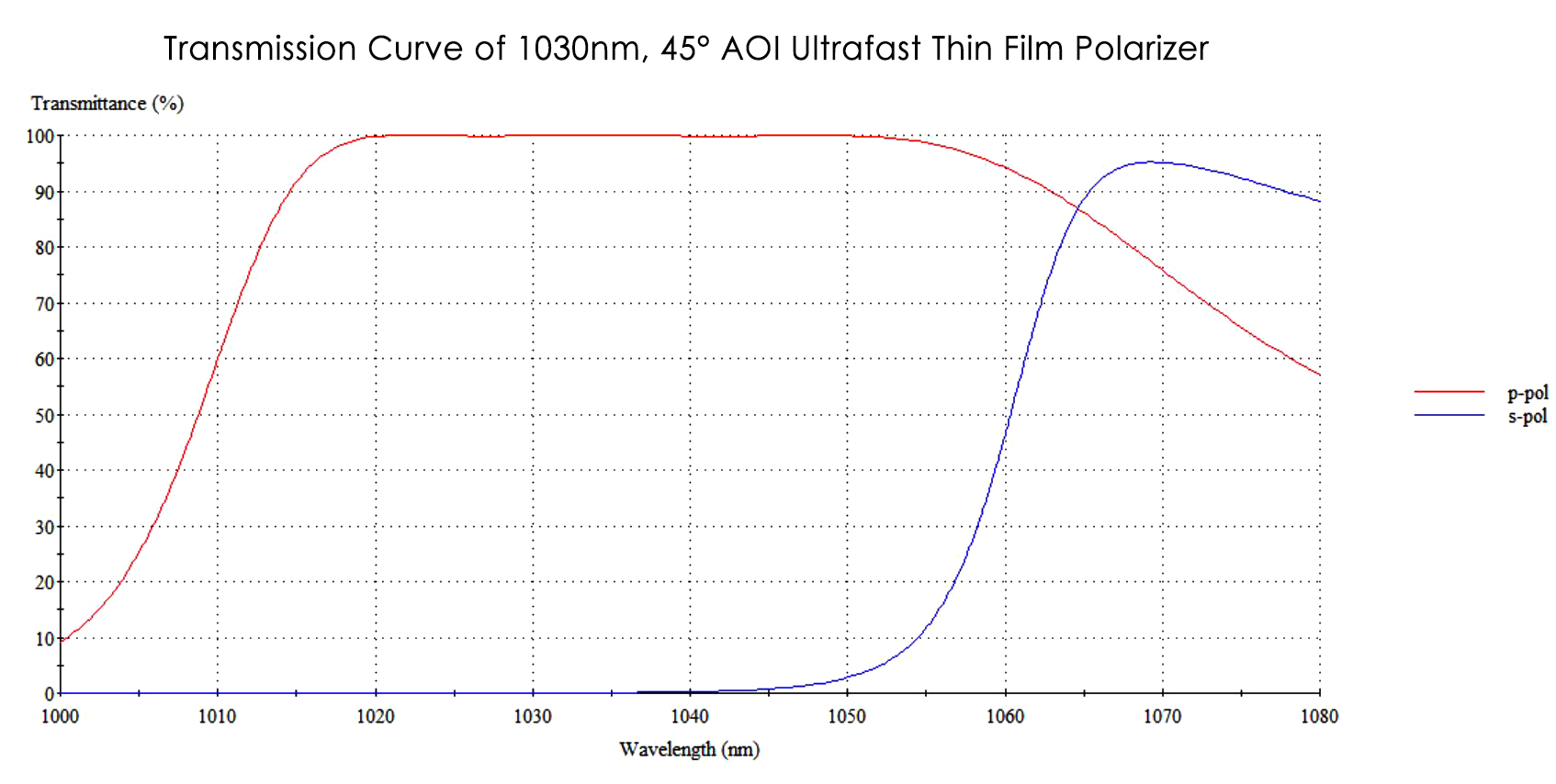

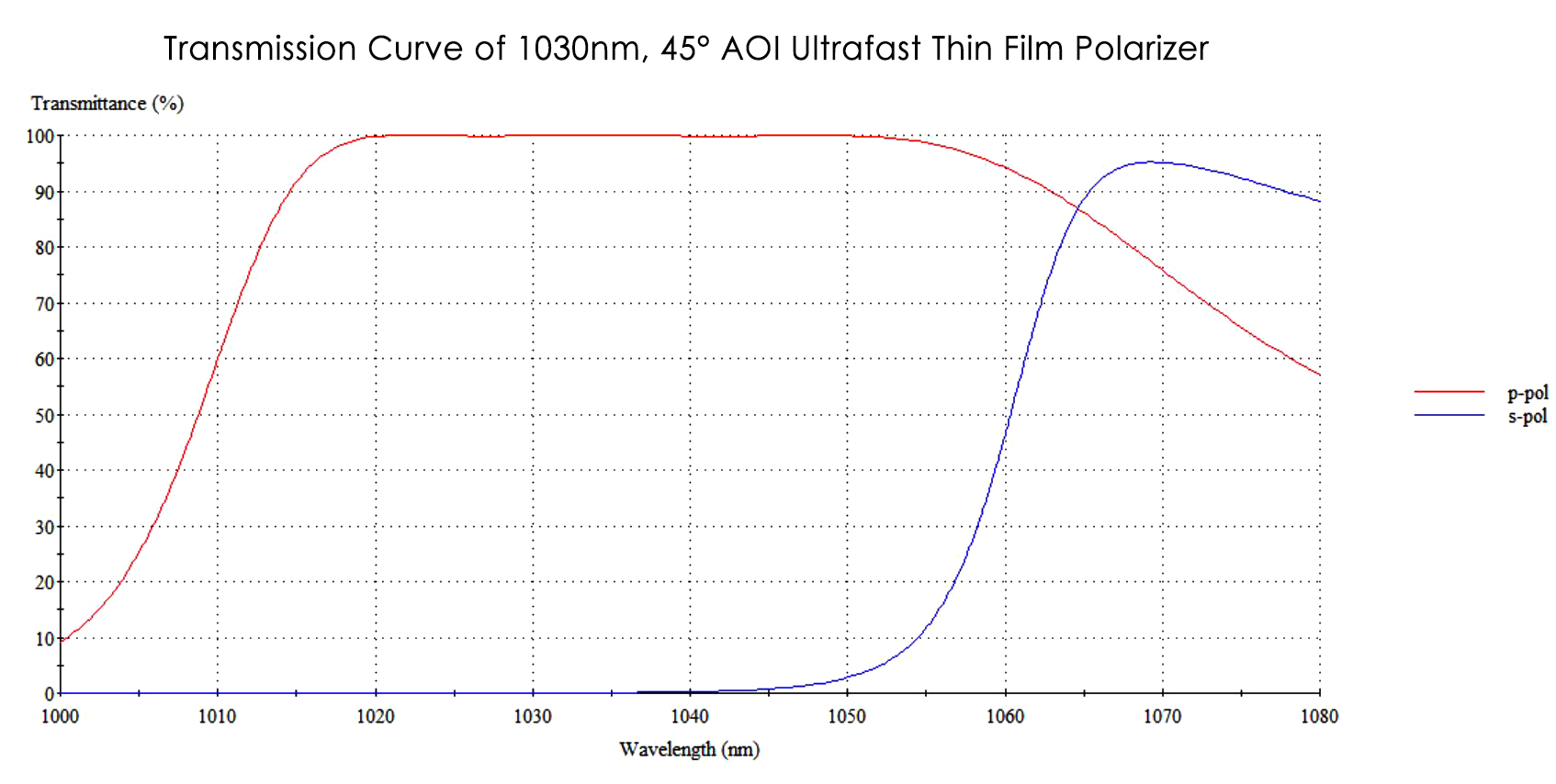

1. Transmission curve of the s and p polarization of 1030nm wavelength, 45deg AOI thin film polarizers for femtosecond lasers

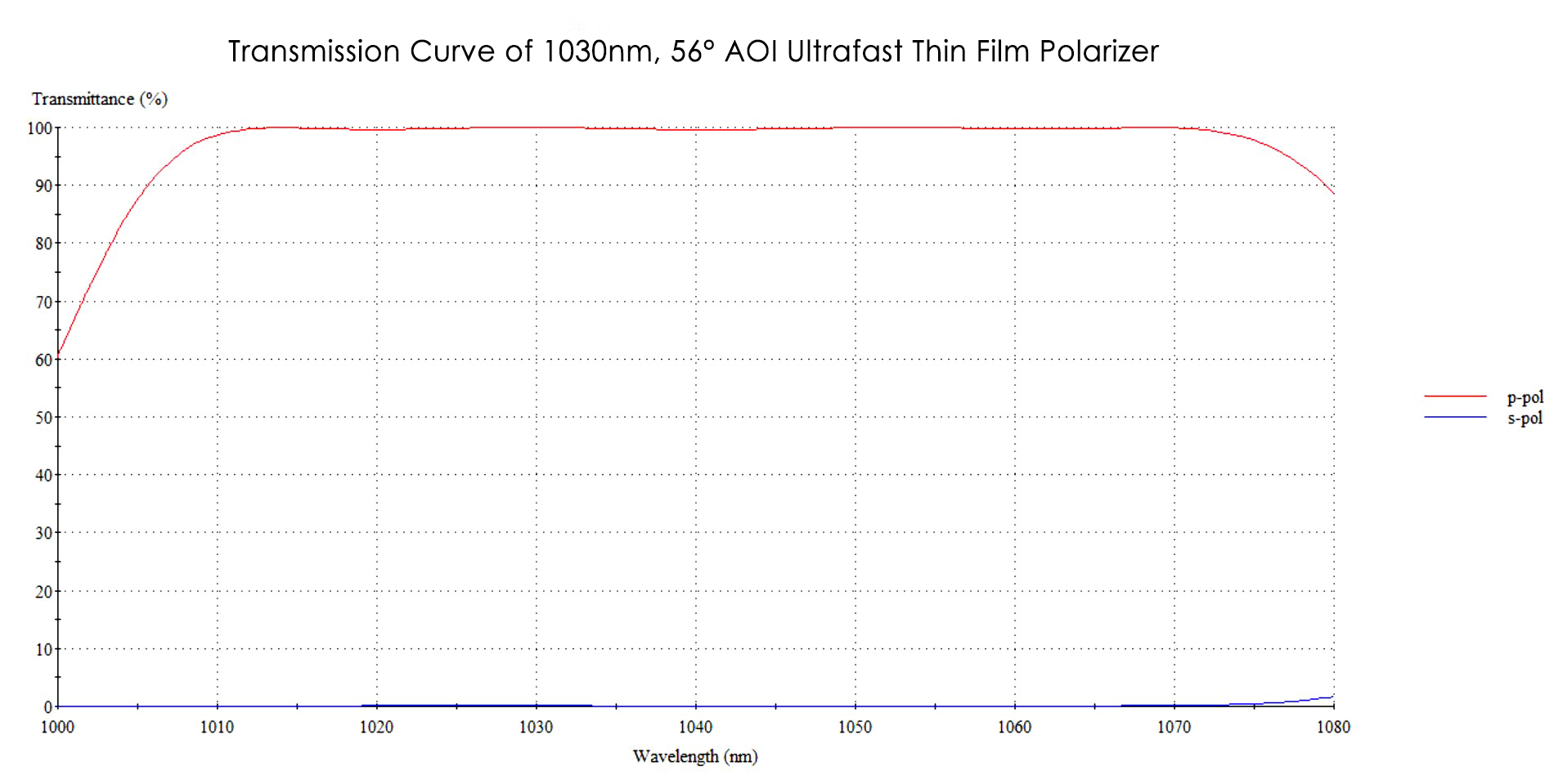

2. Transmission curve of the s and p polarization of 1030nm wavelength, 56deg AOI thin film polarizers for femtosecond lasers

Dia12.7mm, 515nm, 56° AOI, Thin Film Polarizers for Yb Ultrafast Laser

Dia25.4mm, 1030nm, 45° AOI, Thin Film Polarizers for Yb Ultrafast Laser

Dia25.4mm, 515nm, 45° AOI, Thin Film Polarizers for Yb Ultrafast Laser