After slicing, the axial planes of sapphire blanks (which are the functional planes of sapphire windows) will be ground. This procedure aims to shape the element into the appropriate thickness, eliminate the scratches and defects on the functional planes, reduce the roughness and elevate the flatness until the sapphire substrates are prepared for polishing.

The grinding techniques for single crystal sapphire windows are manifold, including Mechanical Grinding, Chemical-Mechanical Grinding (PCG), ELID, etc. Sapphire is a brittle and stiff material with extraordinary hardness, so it would be difficult to balance strength and precision during the grinding course.

1)Mechanical Grinding of Sapphire Windows:

The traditional grinding technique is mechanical grinding. It uses fluid abrasive slurries, consisting of abrasive particles of greater hardness poured onto grinding pads to exert mechanical forces onto the sapphire elements to remove the excessive sapphire. As the grinding pad spins, the fluid slurries come into contact with the sapphire substrate and the particles inside perform a powerful mechanical removal. Common abrasive slurries are made from W40 boron carbide + W7/W10 boron carbide as the abrasive slurries. Boron Carbide, with molecular formula BC4, is also known as “black diamond”, and is one the hardest materials known (the Mohs index of BC4 is 9.5, while sapphires’ is 9). The densities and the sizes of the abrasive particles could be modified according to different precision and speed standards. In the initial grinding phase, coarse-grain grinding slurries are chosen, and later in a finer grinding and lapping stage, fine-grained grinding slurries will be used. Apart from the slurries, no chemical solutions are added, just ionized water is applied to flush the removed sapphire materials down.

Along with the rapid growth of sapphire-based technologies, ultra-thin and high-precision sapphire windows also embrace growing demand. This poses big challenges to the traditional grinding techniques of sapphire elements. As this pure-mechanical method uses abrasion particles of greater hardness than sapphire, the material removal strength could be too vigorous, causing unpredictable scratches and minor injuries, lowered surface qualities and concentration of stress within the sapphire substrates, affecting the live span of the sapphire windows.

2)Chemical Mechanical Grinding of Sapphire Windows

A modification to the aforesaid pure-mechanical method is Chemical Mechanical Grinding (CMG). This method also uses fluid grinding slurries, but the abrasive particles are made from materials of similar hardness to sapphire, such as corundum, SiC, etc. Since the abrasive particles are of similar hardness to sapphire, chemical grinding solutions must be utilized in conjunction to strengthen the material removal. Strong, corrosive acid or alkaline solutions are chosen. The acid or alkaline weakens the covalent bond of sapphire atoms on the front surface of sapphire substrates and forms a softened section, then mechanical forces remove the softened section, realizing material removal. This CMG technique provides more delicate grinding controls and helps to obtain smoother sapphire window surfaces.

However, the consumption of slurries leads to rising production costs, redundant slurries also derive environmental contamination. Besides, in the grinding course, the loose abrasives in the slurries move in spontaneous manners, it’s difficult to control the grinding course, and loose particles might cause unpredictable damage to the sapphire windows’ surface.

3)Fixed Abrasive Chemical Mechanical Grinding of Sapphire

In recent years, multiple innovations have been developed in the market in response to these problems. One of them is Fixed Abrasive Chemical Mechanical Grinding (FA-CMG), the abrasive particles are fixed with the grinding pad instead of moving in a loose manner within the grinding fluid. One approach of FA-CMG is using grinding plates embedded with diamond particle grids, in combination with a grinding lubricant composing ionized mixed with 2% ethanediol. The ethanediol composition helps to increase the activeness of the surface of sapphire substrates, softening the contact interface, enhancing the material removal speed, and improving the surface qualities. The major advantage of this approach is the reduced uncertainties attributed to the fixed abrasion particles. And because the abrasive particles have been planted into the grinding plate, additional grinding slurries are not needed, saving the production cost.

4)Fixed Soft Abrasive Grinding (FSAG) of Sapphire

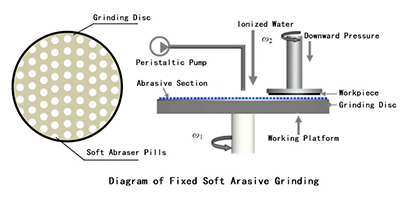

There is also the Fixed Soft Abrasive Grinding (FSAG) technique. Compared with FA-CMG, in the fixed soft abrasive grinding technique no liquid form chemical solutions are added during the grinding course, and the abrasive particles are made from materials softer than sapphire (e.g Silicon Dioxide, Magnesium Oxide). Removal of sapphire is realized based on a solid phase chemical reaction between the sapphire window substrate and the fixed abrasives. According to the chemical, and physical properties and the micro-structures of single crystal sapphire, using specific abrasives (to minimize the potential damage, the hardness of the abrasive must be pertinent) that makes chemical reaction with sapphire (and the product of chemical reactions can be removed at ease). The operation details are stated as follows:

Mixtures of SiO2 or MgO, Fe2O3 particles, phenolic resin, NaCO3, and KmnO4 are pressed into a batch of circular abraser pills, the abraser pills are then distributed with caution on a grinding disc that rotates. The SiO2 and MgO, Fe2O3 particles are the main contents, making chemical reactions with sapphire under certain conditions, the phenolic resin and NaCO3 are the bonding agents, increasing the porosity and self-sharpening characteristic of the abraser pills, and KMnO4 is the active agent which helps to promote the reaction speed.

As the grinding disc rotates, a great amount of heat is generated at the contact area between sapphire and abraser pills, leading to a substantial temperature rise reaching the solid phase chemical reaction temperature of the substances. Meanwhile, the active and bonding agents within the abraser pills keep spreading boosting and PH modulation doses onto the front face of the sapphire, thus solid-phase chemical reactions are triggered between the soft abraser pills and sapphire window substrate. The result of the chemical reaction is a softened portion at the interface. The softened portion is lower than the sapphire and could be easily removed. The abrasive particles then perform moderate, microscale mechanical material removals. Because the abrasive materials are softer than sapphire, the danger of surface damage plummets. Furthermore, this fixed soft abrasive grinding technique does not use grinding slurries and chemical grinding solutions, which helps to cut the production cost down and reduce environmental harmfulness.

Figure 1. Set of Fixed Soft Abrasive Grinding

5)ELID (Electrolytic In-process Dressing) Grinding of Sapphire Windows

There is also an ELID (Electrolytic In-process Dressing) sapphire grinding technique utilizing a diamond grinding wheel and the electrolyzation effect. In the grinding process, the surfaces of the diamond abrasives on the diamond grinding wheel are continuously refreshed by the electrochemical reaction. ELID grinding technique is often adopted to produce ultra-high-precision sapphire windows.