Composite Laser Crystal Tutorial

Product Name: Composite laser crystal

Simplified chemical formula:

- For Nd:YAG+Cr:YAG crystal: Nd :YAG (Nd:Y₃Al5O₁2) + Cr:YAG (Cr:Y₃Al₅O₁2)

- For YAG+Nd:YAG+Cr:YAG crystal: YAG (Y₃Al₅O₁₂) + Nd :YAG (Nd:Y₃Al₅O₁₂) + Cr:YAG (Cr:Y₃Al₅O₁₂)

Material composition:

- For Nd:YAG+Cr:YAG crystal: (Composition: yttrium 41.2%, aluminum 20.8%, oxygen 37.0% , rare earth 0.6 %, chromium 0.4 % )

- For YAG+Nd:YAG+Cr:YAG crystal: (Composition: Yttrium 41.2%, Aluminum 20.8%, Oxygen 37.0%, Neodymium 0.5%, Chromium: 0.5%)

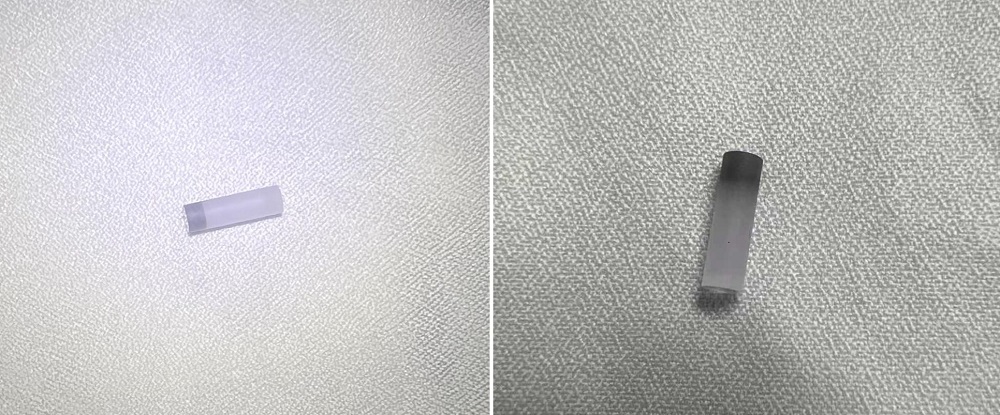

Product images:

Product General Introduction

Composite laser crystals , or diffusion-bonding laser crystals, are composite crystal materials made by physically connecting separate laser crystals through a special process called diffusion-bonding technology. The principle is as follows:

Made up of independent finished crystals connected together: The composite laser crystal is made up of pre-grown independent crystals, which are tightly connected like splicing building blocks.

The joining process is a physical union and does not create new substances: the "diffusion bonding" technology used is a high-temperature, high-pressure process. This process simply brings the contact surfaces of the crystals together at the atomic level, causing a chemical reaction. It does not change the original chemical composition and physical structure of the individual crystals, nor does it create any new chemical components.

In both of these independent crystals, the yttrium element exists in a very stable, inseparable chemical state (chemically bonded to elements such as aluminum and oxygen) within the crystal structure, rather than as a single element or simple compound. The bonding process does not alter this stable state.

There are two common matches for the composite laser crystals:

- Nd:YAG+Cr: YAG composite laser crystal, for the generation of 1064nm Q-switched laser

- YAG+Nd:YAG+Cr:YAG composite laser crystal, also for for generation of 1064nm Q-switched laser, but the additional YAG composition serves as an end cap to dissipate heat and improve the thermal stability.

Other compostions include:

YAG+Nd :YAG+YAG

YAG+Cr4+ :YAG

YAG+Nd :YAG

YAG+Nd:YAG+Cr4+:YAG+YAG

YAG+Cr4+:YAG+Nd:Ce:YAG+YAG

YVO4+Nd:YVO4+YVO4

These are all available in Shalom EO. And the doping percentage of Nd can change according to the customer’s requirement too. But in this article from Shalom EO, we are only going to discuss Nd:YAG+Cr: YAG or YAG+Nd:YAG+Cr:YAG as two common examples.

The following are descriptions of two types of composite laser crystals:

Nd:YAG+Cr: YAG composite laser crystal, consisting of:

1. Yttrium aluminum garnet crystal (Nd:YAG)

yttrium aluminum garnet (YAG), with the simplified chemical formula Nd:YAG, is formed by the incorporation of trivalent negative ions (Nd³⁺) into the YAG lattice. It acts as a laser medium within the composite laser rod. When pumped, YAG emits 1064 nm laser light, demonstrating high quantum efficiency, long fluorescence lifetime, and excellent thermomechanical properties.

2. Chrome-plated yttrium aluminum garnet crystal (Cr: YAG)

Aluminum-coated garnet crystal, chemically known as Cr: YAG, is an absorber made by plating chromium ions (Cr⁴⁺) in YAG. It serves as a Q regulator in the composite laser rod bonding rod, enabling laser pulse output. Its physical and chemical properties are consistent with those of YAG crystal , with a high damage threshold and excellent thermal stability.

The diffusion bonding crystal fully utilizes the high laser gain characteristics of Nd: YAG and the corresponding absorption characteristics of Cr: YAG to achieve efficient, simple, and high damage threshold laser output.

Nd:YAG+Cr:YAG laser crystal bonded rods retain the cubic structure of the YAG matrix, offering optical isotropy, high mechanical properties (Mohs scale approximately 8.5), a high melting point (approximately 1950°C), and resistance to water, common acids, and bases. Their structural stability makes them suitable for high-power lasers and high-repetition-rate pulsed lasers.

YAG+Nd:YAG+Cr:YAG composite laser crystal, consisting of:

1. Yttrium aluminum garnet crystal (YAG)

Yttrium aluminum garnet (YAG) crystals, with the simplified chemical formula YAG, have a cubic structure and possess excellent optical isotropy, high hardness (approximately 8.5 on the Mohs scale), a high melting point (approximately 1950°C), and good chemical stability. They are insoluble in water and common acids and bases. In YAG crystal bonding rods, YAG typically serves as end caps, dissipating heat and preventing end face damage.

2. Neodymium-doped yttrium aluminum garnet (Nd: YAG)

3. Chromium-doped yttrium aluminum garnet crystal (Cr :YAG)

Compared to the Nd:YAG+Cr:YAG laser rod, YAG+Nd:YAG+Cr: YAG, with the additional YAG section as the end cap, the following aspects are optimized:

Heat Management: When a laser is pumped (excited by the lamp or diode), the Nd:YAG gain medium absorbs the energy, but not all of it converts into laser light; a significant portion turns into heat. This heat is concentrated near the end face where the pump light enters. The undoped YAG end cap acts as an effective heat sink due to its high thermal conductivity (a key characteristic of YAG crystals ).

Reduced Thermal Lensing/Stress: By drawing heat away from the excited region, the YAG cap reduces the temperature gradient across the laser rod's cross-section. This minimizes thermal lensing (a change in the refractive index due to heat, which distorts the beam) and thermal stress, leading to a higher quality beam and more stable laser operation, especially at high power or high repetition rates.

Growth of the Crystals:

YAG crystal blank growth: YAG crystal blanks are grown using the Czochralski method, a high-temperature chemical reaction process . High-purity yttrium oxide (Y₂O₃) and aluminum oxide (Al₂O₃) are mixed in a 3:5 molar ratio and heated in a high-temperature furnace until they are completely melted. A YAG seed crystal is then slowly pulled from the melt using the Czochralski method. By precisely controlling the temperature gradient, pulling rate, and rotational speed, the melt recrystallizes on the seed crystal, resulting in the growth of a complete YAG single crystal. The entire growth process includes key steps such as raw material melting, crystal nucleation, isodiametric growth, and annealing cooling.

Neodymium-doped yttrium aluminum garnet ( Nd:YAG) crystal blanks are prepared by mixing high-purity Y₂O₃ , Al₂O₃, and Nd₂O₃ in precise proportions. These are then melted at temperatures exceeding 1970°C (typically in a molybdenum crucible under an inert or reducing atmosphere). This high-temperature chemical reaction forms a uniform Nd:YAG melt, which is then grown using the Czochralski method. The growth process includes raw material pretreatment and proportioning, high-temperature melting and chemical reaction, seeding, necking and shoulder reduction, uniform diameter growth, and annealing. The entire process requires precise control of the Nd³⁺ doping concentration to ensure uniform ion distribution throughout the crystal.

Cr-doped YAG crystal growth : Cr-doped YAG blanks are similarly produced through high-temperature chemical reactions : Y₂O₃, Al₂O₃, and Cr₂O₃ are mixed in a designed ratio, heated to above 1970°C in a high-temperature furnace to melt, and then grown using the Czochralski method . The key is to precisely control the growth atmosphere and temperature field to ensure that Cr ions enter the YAG lattice at the desired valence and concentration.

Diffusion bonding process

The crystals are joined together using diffusion bonding to form a Nd:YAG+Cr:YAG bonded crystal rod. Diffusion bonding is a physical technique for joining dissimilar crystals that requires no modifiers. First, the contact surfaces of the two crystals are precisely machined to atomic-scale gratings and tightly aligned. Heat treatment at high temperatures allows the atoms at the interface to diffuse into each other, forming a permanent, rigid bond.

Composite laser crystals are often made into rods with a diameter and length according to customer requirements . The light-emitting surface needs to be precisely polished and coated with an anti-reflection film.

Working principle

The operating principle of the composite laser rod is based on the synergistic effect of its component crystals. Through precise energy level design and optical structure, it achieves efficient pulsed laser output , specifically at a wavelength of 1064nm .

After precision machining and appropriate optical coating , the crystal bonding rod is combined with components such as a high-reflection mirror and an output mirror and installed in the laser cavity. When energy is input into the crystal bonding rod through a pump source such as a halogen lamp or a laser diode , the crystal rod outputs a pulsed laser at 1064nm.

Production process

- Crystal blank growth

- Before bonding : A diamond wire saw is used to perform preliminary cutting of the constituent crystal blank to obtain the required geometric shape . Each crystal contact surface is then precision polished and ultrasonically cleaned to achieve atomic-level condition and cleanliness Diffusion bonding is a process for joining crystals: in an ultra-clean environment, the constituent crystals are precisely aligned and positioned in a high-temperature furnace. Under a specific temperature (approximately 1000-1200°C) and pressure, atoms diffuse across the interface, forming an intermittent bond with excellent optical properties. This physical bond relies on van der Waals forces .

- Lose: After the bond is completed proceed slowly to ease elimination.

- Precision machining: Milling, grinding, polishing and other precision machining processes are used to ensure that the crystals meet strict geometric tolerances and excellent optical surface quality.

- Surface treatment: Coat the required dielectric film (anti-reflection film or reflective film) on the polished crystal surface as required.

Application areas

- Industrial laser processing: marking, cutting, welding, etc.

- Medical equipment: laser surgery, skin treatment, etc.

- Laser experiments and nonlinear research in the field of optical research

Related Products

Tags: composite laser crystal