Why Gold Coating Remains Irreplaceable?

In optical drawings and purchase specifications, the term “Gold Coated” is often highlighted as a standalone requirement.

At first glance, it may appear to be a premium or even conservative choice. In practice, however, gold coatings are specified not because they are expensive, but because they solve a set of engineering problems that few other materials can address simultaneously.

In infrared optics and electro-optic (EO) systems, gold coatings are typically chosen for three reasons: stable infrared reflectivity, long-term environmental reliability, and electrical stability under high-voltage operation.

This article examines these roles from an engineering perspective and explains when gold coating is essential, and when it is not.

________________________________________

1. What Gold Coating Really Means in Optical Engineering

From an engineering standpoint, optical gold coatings are not about appearance. Their value lies in predictability.

Infrared performance is the most obvious factor. Gold maintains a high and relatively flat reflectance from the near-infrared (NIR) to the far-infrared (FIR) region. For infrared lasers, thermal imaging, and IR sensing systems, spectral stability across the operating band is often more critical than peak reflectance at a single wavelength.

Chemical stability is the second key advantage. Gold is effectively immune to oxidation and corrosion. In humid environments, outdoor installations, or systems designed for long operational lifetimes, this stability translates directly into slower performance drift and longer recalibration intervals.

It is important to note that gold is not universally optimal. In the visible spectrum, its reflectance is clearly inferior to silver, and in cost-sensitive or short-lifetime systems it may be unnecessary. However, once a system moves into infrared wavelengths or long-term reliability becomes a priority, engineering trade-offs frequently favor gold.

________________________________________

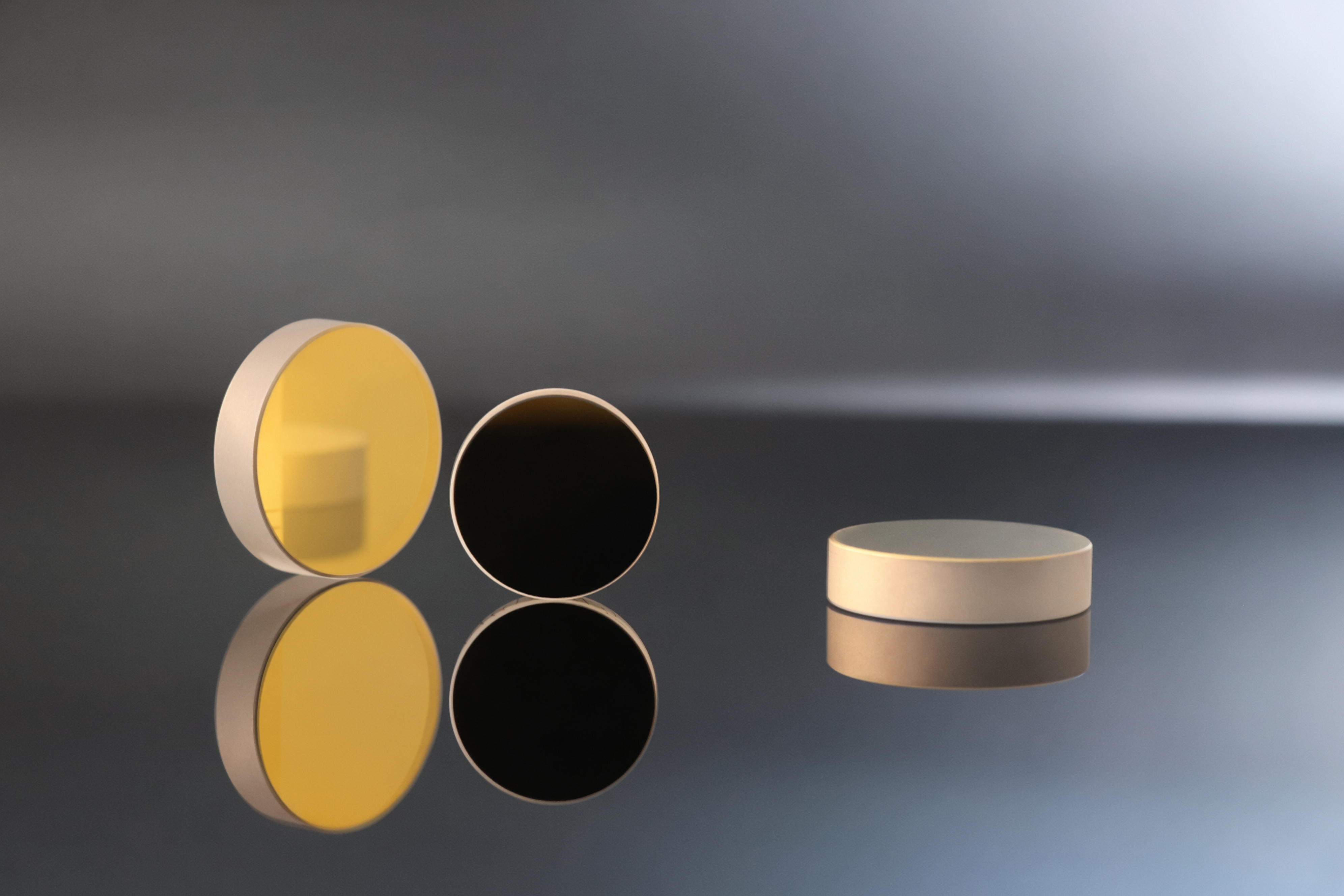

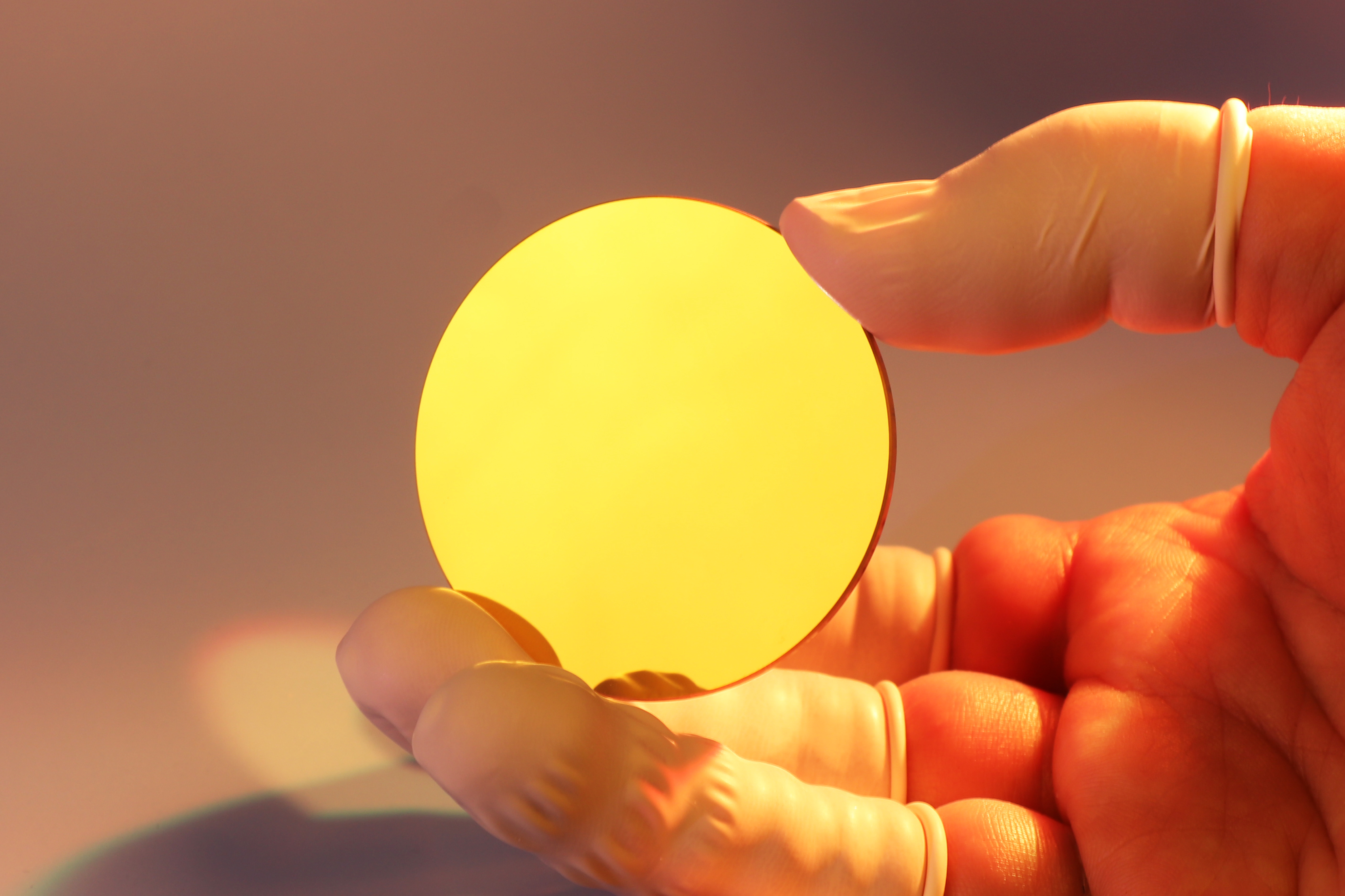

2. Gold in Metallic Mirrors: A Stability Baseline for Infrared Systems

The role of gold is most straightforward in metallic mirrors.

When designing mirrors on substrates such as UV fused silica, the coating choice typically comes down to aluminum, silver, or gold. The difference is not a matter of quality, but of operating regime.

Coating Type |

Enhanced Al |

Protected Ag |

Protected Au |

Key Strengths |

Broad spectral coverage, cost-effective |

Highest reflectivity in VIS–NIR |

Stable NIR–FIR reflectivity, corrosion resistance |

Typical Use Cases |

General laboratory optics, beam steering |

Imaging and detection systems |

IR lasers, thermal optics, outdoor or long-cycle systems |

In infrared laser systems, radiometric setups, or thermally sensitive assemblies, protected gold coatings are often selected as a risk-reduction measure. Their advantage lies less in absolute performance on day one and more in maintaining consistent optical behavior after thousands of operating hours.

________________________________________

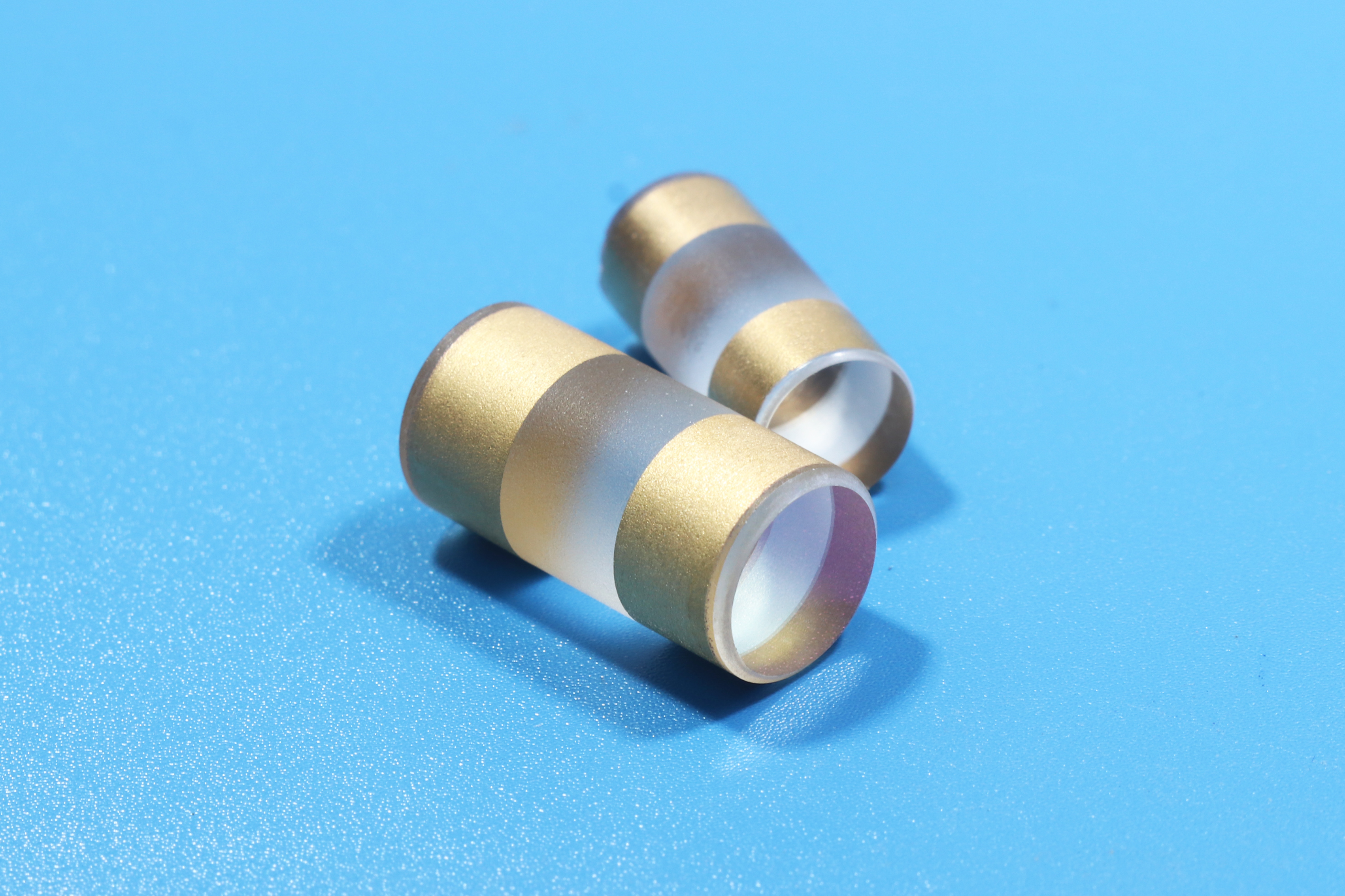

3. Cr+Au on BBO Crystals: Gold as a Reliability-Driven Electrode Material

In electro-optic systems, gold serves a fundamentally different purpose.

For BBO crystals used in Pockels cells and Q-switches, Cr+Au electrode systems are widely regarded as an industry standard. Here, gold is not an optical coating but a critical electrical interface.

A typical structure consists of:

• a thin chromium layer to promote adhesion to the crystal surface

• a gold layer to provide low resistivity and oxidation resistance.

The engineering concern in these systems is not initial conductivity, but long-term electrical integrity. Degradation of electrode surfaces can lead to increased contact resistance, local field distortion, or unstable high-voltage modulation. Gold’s chemical inertness directly mitigates these failure modes, extending device lifetime under demanding operating conditions.

________________________________________

4. A Necessary Contrast: When Gold Is Not the Right Tool

Understanding where gold is indispensable also clarifies where it is not.

Optical filters—such as longpass or bandpass filters—are designed around multilayer dielectric interference rather than metallic reflection. Their purpose is precise spectral shaping, not broadband reflection or electrical conduction.

This distinction is critical during system design:

Optical Function |

Broadband reflection |

Spectral selection |

High-speed EO modulation |

Typical Coating Strategy |

Metallic coatings (Al, Ag, Au) |

Dielectric multilayer coatings |

Cr+Au electrode systems |

Applying gold where dielectric interference is required adds cost without functional benefit.

________________________________________

5. Three Engineering Questions That Matter More Than “Do I Need Gold?”

In practical system design, asking the right questions is more effective than defaulting to a specific coating.

Q1: What is the operating wavelength?

For 200–1000 nm applications, aluminum or silver often provides better value. Beyond 1 μm, especially in infrared systems, gold becomes increasingly advantageous.

Q2: Is the function reflection, transmission, or modulation?

Metallic mirrors, optical filters, and EO devices impose fundamentally different coating requirements.

Q3: Is long-term stability more critical than initial cost?

In systems where uptime, environmental exposure, or service intervals matter, gold coatings often function as a reliability tool rather than a luxury.

From a handling perspective, protected gold mirrors and exposed Cr+Au electrodes should be treated differently. While protected Au mirrors include a mechanical overcoat, electrode surfaces must be shielded from abrasion and aggressive solvents to preserve electrical continuity.

Figure. Custom aluminium-based optical mirror, Ø160 × 160 × 18 mm, featuring a protected gold coating. Designed for stable reflectivity in near- to far-infrared applications, where long-term performance and environmental durability are required.

________________________________________

Final Note

Gold coating is neither a default choice nor a cosmetic upgrade. Its continued use in infrared and electro-optic systems reflects the fact that, under specific conditions, it delivers predictable optical and electrical behavior over long periods of operation.

When evaluating infrared mirrors, EO crystal electrodes, or trade-offs between aluminum, silver, and gold, system lifetime, environment, and functional requirements often provide clearer guidance than specification tables alone.

In many cases, engineering judgment is not about material cost; it is what ultimately points to gold.