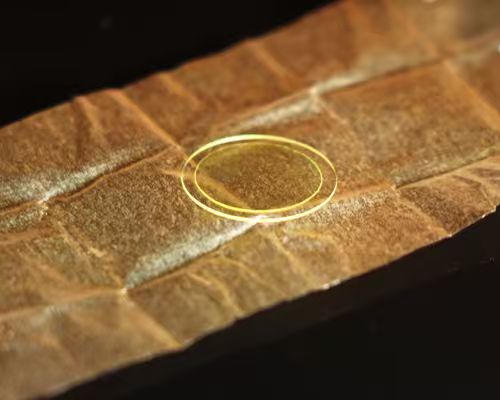

Ce:YAG Scintillator Screen with Fused Silica Substrate

Product Name: Yttrium Aluminum Garnet Crystals with Substrate

Product Overview and Material Composition

The yttrium aluminum garnet crystal with a substrate is composed of cerium-doped yttrium aluminum garnet crystal and a fused silica glass substrate. The reason for combining the crystal with the glass substrate is that the crystal needs to be processed very thin for application requirements; such thinness would make the crystal brittle and fragile. Therefore, a substrate is added to support the crystal.

Cerium-doped yttrium aluminum garnet crystals, simplified chemical formula Ce:YAG , are made of crystal material (main components: 45% yttrium, 22.5% aluminum, 32.3% oxygen, and 0.2% cerium) . In this product, the Ce:YAG crystals are the main functional component.

The fused silica glass substrate is made of silica glass (mainly composed of 46.67% silicon and 53.33% oxygen). The function of the glass substrate is to support the crystal.

Product images:

- Product Introduction:

- Product Structure

a component composed of cerium-doped yttrium aluminum garnet crystal and a fused silica glass substrate . This component is commonly used in X-ray or soft X-ray imaging . The production steps are as follows:

- The grown cerium-doped yttrium aluminum garnet (Ce:YAG) crystal blanks are cut and polished to meet the required dimensions, surface shape, and surface finish. To achieve higher spatial resolution and high light output efficiency, the Ce:YAG crystals in this product are processed to a very thin thickness.

- Because cerium-doped yttrium aluminum garnet crystals are processed to extremely thin thicknesses to meet specific requirements, they become brittle and fragile, making conventional handling and processing impossible . Any slight stress or bending would cause the crystal to break. A supporting substrate is needed to prevent the crystal from easily breaking during use. The substrate is made of fused silica glass and is also processed to the appropriate specifications.

- A fused silica substrate is bonded to cerium-doped yttrium aluminum garnet crystals using optical adhesive.

- Cerium-doped yttrium aluminum garnet crystals

Cerium-doped yttrium aluminum garnet crystals, with the simplified chemical formula Ce:YAG, are a common scintillation crystal material. Ce:YAG crystals emit fluorescence with a central wavelength of 550 nm under X-ray or soft X-ray radiation , exhibiting good luminous efficiency, thermal stability, and mechanical strength , making them suitable for X-ray or soft X-ray imaging.

Cerium-doped yttrium aluminum garnet crystals are prepared by thoroughly mixing yttrium oxide and aluminum oxide raw materials, then incorporating cerium oxide, followed by a high-temperature chemical reaction and Czochralski crystal growth technique. Elemental yttrium exists in an inseparable form within the crystal.

- Yttrium aluminum garnet crystals with substrate

Cerium-doped yttrium aluminum garnet crystals are processed into very thin sheets, which are then bonded to a fused silica substrate using a photopolymerization process. When high-energy particles (such as X-ray photons) irradiate the Ce:YAG crystal, the cerium ions in the crystal emit a 550nm yellow-green fluorescence. These fluorescence signals can be converted into electrical and digital signals by backend electronic devices (this product itself does not contain electronic devices), and then calculated by a host computer to obtain a visible image.

Cerium-doped yttrium aluminum garnet crystals emit fluorescence, while the fused silica glass combined with them has high light transmittance , thermal stability, and radiation resistance , which can effectively protect the crystal , provide mechanical support for the crystal, and prevent the crystal from deforming or breaking due to excessive thinness .

- Working principle- How are Ce:YAG screens used in X-ray and soft X-ray imaging

This product is assembled from cerium-doped yttrium aluminum garnet crystals and a fused silica glass substrate using a photopolymerization process. It is a radiation detection element primarily used in X-ray and soft X-ray imaging. The cerium-doped yttrium aluminum garnet crystals function as fluorescent emitters, while the fused silica glass substrate provides mechanical support for the crystal.

In X-ray imaging or soft X-ray imaging applications, cerium-doped yttrium aluminum garnet ( Ce:YAG ) crystals serve to convert X-rays or other high-energy radiation into measurable fluorescence signals. The principle is:

- X-ray tubes in X-ray imaging instruments emit X-rays, which penetrate the object being detected. Because the object's density and thickness differ, the intensity of the X-rays penetrating the object also varies.

- These X-rays of varying intensities, after penetrating the object, irradiate the detector in the imaging instrument, the core component of which is this product. The cerium ions in the cerium-doped yttrium aluminum garnet crystal in this product emit fluorescence under X -ray or other radiation, with a central wavelength of approximately 550 nm . The fluorescence intensity is closely related to the intensity and energy of the radiation. By fabricating Ce:YAG into a very thin sheet, the fluorescence signal can achieve higher spatial resolution and light output efficiency. Simultaneously, combined with a fused silica glass substrate, the crystal receives mechanical support, making it less prone to breakage and more stable.

- The electronic components in the imaging instrument convert the fluorescence signal emitted by the product into an electrical signal, and then into a digital signal. Finally, the host computer calculates the X-ray image reflecting the internal structural characteristics of the object based on the signal intensity .

3.Production Process:

1. Growth of cerium-doped yttrium aluminum garnet crystal blanks : Yttrium oxide, aluminum oxide, and cerium oxide are mixed and placed in a crucible. The crucible is placed in a Czochralski single crystal furnace, and cerium-doped yttrium aluminum garnet crystals are grown through a high-temperature chemical reaction using the Czochralski method. In this process, yttrium exists in an inseparable and stable form within the crystal lattice.

2. Cerium-doped Yttrium Aluminum Garnet Crystal Cutting and Processing : Crystals are cut to the dimensions specified by the customer. The crystal end faces are treated for parallelism, followed by fine grinding and optical-grade polishing to ensure surface accuracy and smoothness meet optical standards. Typically, Ce:YAG crystals are processed to a very thin thickness in this product.

3. Glass blank preparation: Fused silica glass blanks are prepared by gas refining using silicon compounds as raw materials.

4. Glass substrate preparation: The fused silica glass blank is cut into the required shape and size, and then ground and polished to make the glass substrate meet the optical grade standard, thus obtaining the fused silica glass substrate.

5. Glass substrate bonding: A fused silica substrate is bonded to a cerium-doped yttrium aluminum garnet crystal using optical adhesive. A layer of optical adhesive is applied to the surface of the fused silica substrate, and then a cerium-doped yttrium aluminum garnet crystal sheet is placed on top. After the optical adhesive cures, the two are fixed together.

6. Testing and Packaging : Dimensions, parallelism, and performance are tested in a clean environment, and the products are packaged after passing the tests .

- Application Areas:

This product is mainly used to manufacture high-resolution X-ray and soft X-ray imaging equipment, and is suitable for fields such as medical imaging, non-destructive testing, scientific research and exploration, and industrial imaging.

Tags: YAG:Ce Scintillation Screen