Dispersion Compensation Chirped Mirrors

What is Dispersion Compensation in Femtosecond Pulsed Lasers?

A large number of theoretical and experimental studies have found that the control of dispersion in the laser cavity is a key factor in the formation of ultrashort laser pulses in mode-locked laser systems. (You might also learn more about ultrafast lasers by clicking the link)

Femtosecond lasers produce extremely short pulses (on the order of 10^-15 seconds). These ultra-short pulses naturally have an extensive spectral bandwidth due to the Fourier transform limit. As pulses get shorter, their spectral content spans a wider range of wavelengths. However, when these pulses pass through optical materials (such as lenses, glass, or air), the different wavelengths travel at different speeds—a phenomenon called dispersion. Dispersion compensation refers to techniques used to reverse or counteract this dispersion so that the pulse can be compressed back to its original ultrashort duration. It ensures that all the different wavelength components of the pulse arrive at the same time, preserving the pulse’s duration, peak power, and shape.

When we talk about dispersion compensation in ultrafast pulsed lasers, an important concept is group delay dispersion (GDD), also called second-order dispersion. A laser pulse can be regarded as an envelope of multiple wavelength components. Group delay dispersion is the quantitative measure of how much the difference in arrival time that a pulse envelope experiences as it propagates through optical media. Mathematically, it’s the second derivative of phase (φ) concerning angular frequency (ω). The calculation equation of GDD is:

GDD= dω^2/d^2ϕ

The unit of GDD is a square of time, for example, in femtoseconds^2 or picoseconds^2.

Due to chromatic dispersion present in the optical media, as light pulses travel through the optical media, the light naturally accumulates positive group delay dispersion, which is not desirable, as this can lead to the distortion of the temporal profile of laser pulses. Basically, dispersion compensation is to introduce a negative GDD that cancels out the positive GDD.

For pulses shorter than 30fs, third-order dispersion (TOD) also becomes an issue.

In 1984, Fork et al. proposed that prism pairs can be used as dispersion-compensating elements to compensate for dispersion. The introduction of prism pairs provides a tunable negative group delay dispersion that better compensates for the positive dispersion in the cavity from the gain medium in order to obtain laser pulses with as narrow a pulse width as possible.

Although the group delay dispersion (GDD) is well compensated by the use of prism pairs, the higher-order dispersion of the gain medium and the prism material itself is not adequately compensated, which is a serious obstacle to further pulse compression.

Also, conventional dispersion compensation elements (like prisms, gratings, or pairs of mirrors) were originally designed for narrower spectral bands. The original dispersion compensation element is unable to compensate for the dispersion of each order in the wide bandwidth. Therefore, the search for a new type of dispersion element has become a research topic of great interest in the field of femtosecond laser technologies.

The concept of the chirped mirror was first introduced by R. Szipocs and F. Krausz at the University of Vienna, Austria.

Chirped mirrors are a special kind of dispersive Bragg mirror consisting of a substrate and a reflective dielectric coating of multiple thin films with spatially varied thickness. The substrate material is usually made of optical glass or other transparent materials to ensure the transmission and reflection of light. The reflective coatings, on the other hand, consist of multiple layers of thin films, which are mostly made of silicon dioxide, magnesium fluoride, etc., to achieve dispersion compensation while also providing high reflectance.

How Chirped Mirrors Compensate for Dispersion:

The most critical part of a chirped mirror is the coating design. The coating of the chirped mirror offers a negative GDD for each reflection from the chirped mirror, and hence compensates for the dispersion.

Chirped mirrors are coated alternately with thin films of different refractive indices on a specific substrate, and the thickness of the thin films varies according to the dispersion compensation provided. The function of chirped mirror is realized by optical coating. Chirped mirrors are coated using advanced thin-film deposition techniques that allow for precise control over the thickness and sequence of alternating high- and low-refractive-index thin films. Unlike traditional dielectric mirrors (which use uniform quarter-wave stacks), chirped mirrors require non-uniform, carefully engineered structures to achieve broadband dispersion compensation and provide a fixed negative GDD.

Group delay dispersion (GDD) is the rate of change of group delay, which is the time it takes for a wavelength to reflect off the mirror (i.e., how deeply it "penetrates" into the coating before reflecting), with respect to wavelength. Therefore, by controlling the penetration depths of the broadband pulsed laser wavelengths, the GDD value can be deliberately designed.

The core working principle of chirped mirror coating is to use a stack of multiple thin films of alternating low refraction material (e.g., SiO2) and high reflective index material (e.g., Ta2O5), and gradually increasing thickness. The purpose is to make longer wavelengths have lower reflectance for thin films deep down, and hence penetrate deeper into the coatings. The deeper penetration creates the desired time delay between longer wavelengths and shorter wavelengths; the eventual effect is that GDD can be manipulated this way.

To provide a fixed GDD, a chirped mirror must ensure the approximate linear variation of group delay time (penetration depth) against wavelength change.

Here’s why: The maximum group delay dispersion is equal to the ratio of the maximum group delay time and the mirror’s reflective bandwidth, and the maximum group delay is the difference in transmission time from the two boundaries of the reflective wavelength band. Whether the GDD is positive or negative is determined by the design of the chirped mirror film thickness variation trend from the substrate towards the front interface with air. As the film layer gets thinner towards the surface, the long wavelength light travels longer and the short wavelength light travels shorter, the group delay changes to form a negative group delay dispersion, and vice versa to form a positive group delay dispersion. Compared with traditional prism pairs, chirped mirrors can better compensate for the third-order dispersion in the cavity by free design index, which mainly depends on the trend of the slope of the group delay curve.

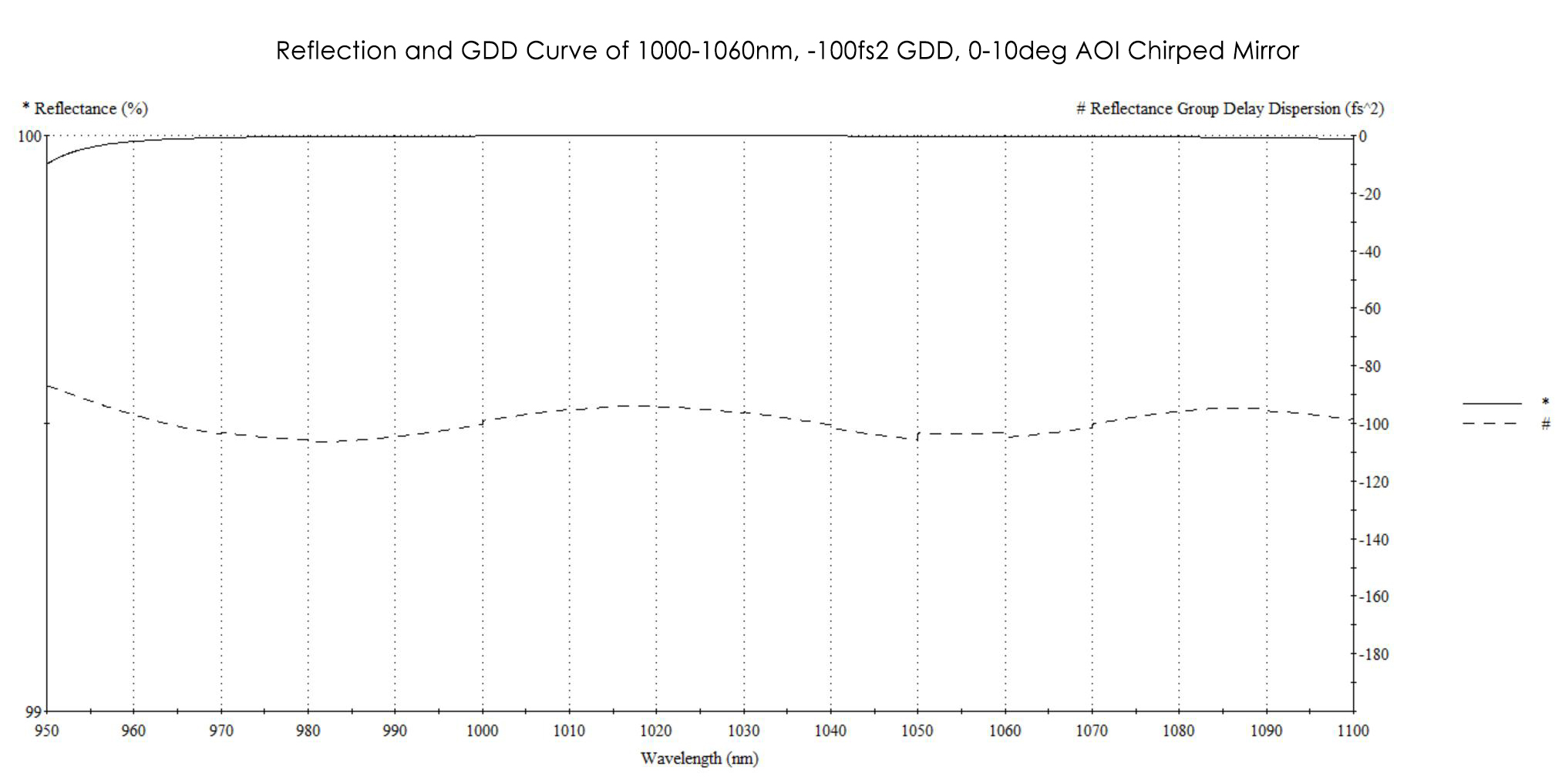

The reflection and GDD curve of a chirped mirror, the chirped mirror is engineered to have -fs2 GDD

GDD Oscillation and Chirped Mirror Pairs

The group delay produced resulting from the reflection of multiple coating layers oscillates greatly across the spectral range, which causes the amount of GDD introduced to exhibit the same violent oscillations. Such oscillations are undesirable, and the spectral phase of the laser pulse passing through such a chirped mirror will be distorted and not achieve the desired effect. Although such oscillations can be attenuated to a certain extent by optimizing the structure of the thin film coating, such optimization is limited by the more stringent initial conditions, i.e., to meet the design requirements of the bandwidth and reflectivity, so it is very difficult to get an effective change. And with further research on the coating principle, two fundamental causes of the group delay oscillation problem have been unearthed:

- The first one is the formation of a kind of F-P resonator structure due to Fresnel Reflection in the surface coating, i.e., the outermost coating in contact with air.

- The second reason is that the light reflected by each layer in a multilayer film structure will undergo a weak mismatch when it re-enters the air after coupling, and this phenomenon will also cause dispersion oscillations.

Since oscillation of group delay is regular along the wavelength axis, a pair of chirped mirrors that can complement each other in terms of dispersion can be obtained through design. The peaks of one against the valleys of another ensure the smoothness of the dispersion curve.

The Applications of Chirped Mirrors

Chirped mirrors have a unique advantage over other structures of dispersion compensation devices, such as compact size, high reflectivities, but the shortcomings, the amount of dispersion provided is relatively limited; after all, chirped mirrors only function based on the thin film coatings. Therefore, chirped mirrors are often used in applications where the amount of dispersion is not large, but where precision and space are required. For example, chirped mirror pairs are often used in ultrafast oscillators to accurately compensate for very small intracavity material dispersion (in combination with prism pairs or spiked pairs). Chirped mirrors are also commonly used in ultrafast laser-based supercontinuum generation processes, where the spectral broadening of an ultrashort laser pulse through a supercontinuum material requires chirped mirrors to compress the pulse to a shorter pulse width.

The figure above shows how a chirped mirror pair evens out the GDD oscillation

Chirped mirrors and chirped mirror pairs are available as stocked and custom versions in Shalom EO. We use high-precison fused silica glass substrates and IAD E-beam coated dielectric chirped coatings. High LIDT and reflection >99.9% @0-10deg AOI, where reflection = (s-polarization+p-polarization)/2 can be obtained. We use ultrafast innovations GOBI white light interferometer to measure the GDD.

Shalom EO's chirped mirrors and the ultrafast innovation's interferometer in our factory

Tags: Dispersion Compensation Chirped Mirrors