Guide to Scintillator’s Application in Nuclear Monitoring

Introduction

Scintillators are materials that produce luminescence when excited by energy sources (such as X-ray, gamma-ray, alpha, and beta particles). The mechanism of luminescence is, when an energy source excites electrons of scintillators to a higher energy state, and they release this energy as photons as they return to a lower energy state. As one of the core working media in the field of radiation detection, it has been used in different industries, including nuclear radiation monitoring, medical imaging, industrial non-destructive testing, oil well logging, high-energy physics experiments, and security inspection.

Different scintillator materials, such as NaI(Tl), LaBr₃(Ce), CeBr₃, LYSO(Ce), GAGG(Ce), plastic scintillators, GOS ceramics, YAG(Ce), CsI(Tl), vary greatly in terms of light yield, decay time, energy resolution, mechanical strength, hygroscopicity, spontaneous emission, and temperature sensitiveness. Therefore, the appropriate material must be selected based on the application scenario.

This technical article will provide a systematic introduction to scintillators used in the nuclear & radiation monitoring applications, including radioactive isotope identification (RIID), surface contamination monitor, and fixed online dose rate monitoring.

In this article, we detail:

- Typical application scenarios of scintillators

- How the detection mechanism works for each application

- The real engineering problems users are trying to solve

- Why are specific scintillator materials are suitable for the application scenarios

In facilities such as nuclear power stations and the Medical Radiology, high levels of nuclear radiation exist in the environment, which makes it essential to have measures to monitor the radioactivity and prevent potential danger and harm to human bodies.

Typical Equipments |

Application Senarios |

Main Challenges |

Working Principle (Simplified) |

Recommended Scintillator Materials |

What Shalom EO Recommends |

RIID (Radioactive Isotope Identifier) gamma spectrometer |

For field inspection, border control, national security, radioactive waste disposal |

• Energy resolution vs. weight vs. battery life |

Gamma radiation→scintillator light → PMT/SiPM → pulse height → energy spectrum → nuclide ID |

NaI(Tl) scintillation crystals and detectors |

NaI(Tl) scintillation crystals and detectors |

LaBr3(Ce) scintillation crystals and detectors |

|||||

Surface Contamination Monitors |

Detect α/β contamination on people, clothing, tools |

• Alpha & beta have short ranges |

α/β strike scintillator → light flashes → PMT → count rate → threshold check → alarm |

ZnS(Ag) for alpha detection |

Phoswich (ZnS+PVT) Plastic Scintillators SP121 (Equal to EJ444) for Alpha Ray & Beta Ray Detection |

PVT Plastic scintillators for beta detection |

|||||

Phoswich (ZnS+PVT) |

|||||

Fixed Online Dose Rate Monitoring Stations |

Continuous monitoring of ambient dose rate |

Wide dynamic range |

Continuous radiation detection → scintillation light → PMT → count rate → Sv/h conversion → alarm if needed |

Plastic scintillators |

Plastic scintillators and detectors |

NaI(Tl) |

|||||

CsI(Tl) |

|||||

GOS ceramics |

Typical Equipment and Applications:

- RIID (Radioactive Isotope Identifier) gamma spectrometer: for field inspection, border control, national security, radioactive waste disposal

- Surface contamination monitor: hand-foot monitors, smear test counters for nuclear power plants Medical Radiology in hospitals

- Fixed online dose-rate monitoring stations: used at nuclear power plants and industrial radiation zones

1. RIID gamma spectrometer:

1.1 Purpose and Challenges of the RIID gamma spectrometer:

Different radionuclides have different gamma energy spectra. The basic function of a RIID gamma spectrometer is to distinguish isotopes based on their characteristic energy peaks using advanced peak-matching algorithms. An RIID gamma spectrometer is often portable (i.e. can be held by hand), allowing workers to carry the device with them and detect the targets.

Figure 1. Nuclear power plants

1.2. Challenges posed for the RIID gamma spectrometer:

The design of a portable RIID gamma spectrometer must balance energy resolution, weight (must be easy to carry), and battery life.

- Energy Resolution: Energy resolution determines how accurately the device can distinguish between different radioactive isotopes. The smaller the value of energy resolution, the sharper the peak, meaning the detector can more easily distinguish particles with similar energies; larger values of energy resolution result in a wider peak and poorer energy discrimination. However, achieving higher resolution often requires larger or more complex detectors (e.g., thicker scintillators or semiconductor detectors), which increases weight and size.

- Weight: A portable device must be easy to carry, especially for field inspections, security checks, or emergency response.

- Battery Life: The device typically needs to operate for several hours in the field. High-resolution detectors or fast data-processing electronics consume more power. Without careful design, battery life may become insufficient.

1.3. The advantages of the Scintillator-based RIID gamma spectrometer

Compared to HPGe semiconductor detectors, scintillator-based radiation spectrometers have certain advantages:

-

No Cryogenics: Scintillators like NaI(Tl) or LaBr₃(Ce) operate at room temperature. Their main rival, HPGe, requires cooling to liquid nitrogen temperatures (~77 K), necessitating bulky, heavy Dewars or mechanical coolers.

- Lower Unit Cost: Scintillator detectors are significantly less expensive to manufacture than HPGe crystals and their associated cooling systems.

- Lower Operational Cost: No recurring cost for liquid nitrogen or significant power draw for cryo-coolers. This allows for wider deployment and use by non-specialist personnel.

- High Density and Z: Materials like NaI are dense and have high atomic numbers, making them excellent at stopping gamma rays. They offer very high photopeak efficiency, especially in common portable sizes. For a given physical size, a scintillator will often have a higher count rate than an HPGe detector, which is crucial for quick screening and detection of weak sources.

1.4. When should you choose Scintillator-based RIID gamma spectrometer

Choose a Scintillator-based RIID when the primary mission requires:

- Rapid screening and alarm over definitive laboratory-grade analysis.

- Operation by first responders, border guards, or technicians in challenging field conditions.

- High probabilities of encountering strong, relatively simple sources (e.g., illicit Cs-137, lost industrial gauges).

- Budget and logistical constraints that preclude cryogenic systems.

Note that scintillator-based RIID still has a much poorer energy resolution than the HpGe detector, leading to wider energy spectrum peaks and problems in peak overlap. We recommend you consult Shalom EO’s professional engineering team for an optimized solution.

1.5. Working Principles of scintillator based RIID gamma spectrometers:

Below is a breakdown of the workflow:

1. Radioactive isotopes (also called radionuclides) emit gamma radiation

Gamma radiation from the radioactive isotopes reaches the detector and passes into the scintillation crystal. Common detection media used include NaI(Tl) scintillation crystals, LaBr3(Ce) scintillation crystals, and GM tubes.

2. The crystal produces flashes of light (scintillation)

The scintillation crystal absorbs the gamma energies and, in response, generates light. The amount of light is proportional to the gamma energies.

3. Light is received by a photodetector(such as a photomultiplier tube or a Si PM) and converted into electrical pulses

4. Electronics measure pulse height

Each electrical pulse has a height (amplitude) that corresponds to the amount of light, which corresponds to the gamma radiation energies. The digital processing units integrated inside the RIID device converts the electrical pulses into digital signals, counts the pulses and sorts them by amplitude, creating a histogram (gamma spectrum). Characteristic peaks appear at known energies.

5. Nuclide identification

The RIID compares the measured peaks with an internal nuclide library. It identifies which radioactive isotope(s) are present based on peak positions and patterns.

1.6. Specific Scintillator Choices in RIIDs:

NaI(Tl) (Thallium-doped Sodium Iodide): NaI(Tl) crystal and detector is The classic workhorse for gamma RIID spectrometer. Offers the best balance of cost, efficiency, and adequate resolution for the most common threats (e.g., Cs-137, Co-60) and industrial isotopes.

LaBr3(Ce)(Cerium-doped Lanthanum Bromide): Scintillation detectors based on LaBr3(Ce) crystals are the premium choice for high-performance RIIDs. It has nearly twice the resolution of NaI(Tl) (~3% at 662 keV), significantly improving identification capability. It is also very fast, helping with dose rate assessment. The trade-offs are higher cost and an intrinsic background from radioactive Lanthanum-138.

RIID gamma spectrometer: Hangzhou Shalom EO provides Handheld Radioactive Isotope Identification Device (RIID) Radiation Detector with high-resolution isotope identification based on NaI(Tl) or LaBr3(Ce) scintillation detectors integrated with silicon photomultiplier (SiPM). Our RIID radiation detector also contains GM tubes for detection and alarm at high dose rates.

Figure 3. Shalom EO's Handheld Radioactive Isotope Identification Device (RIID) Radiation Detector

2. Surface contamination monitors:

2.1. Purpose of surface contamination monitors:Surface contaminations are defined as the presence of radioactive substances in a volume or on a surface where the contamination is unwanted and undesired (air, water, internally in the body, etc.) Surface contamination monitors are instruments used to detect and measure radioactive presence on surfaces, including people, clothing, and equipment, usually from alpha and/or beta emitters.. Surface contaminations are often measured and quantified as radiation rate or radiation dose, allowing determination of whether the surface activities (e.g., Bq/cm²) exceed a set threshold.

Figure 3. Hand and Foot Contamination Monitor

2.2. Challenges posed for Surface Contamination Monitor:

- Optimal Physics for Alpha/Beta Detection: Surface contamination is primarily from alpha and beta particles, which have very short ranges in air. The core challenge of a surface contamination monitor is to discriminate between the short, dense ionization trails of alphas and the more sparse, longer trails of betas, while rejecting the noise from ever-present gamma radiation. For example, many common contaminants (e.g., Cs-137, Co-60) emit both beta and gamma radiation. The instrument must be calibrated correctly to count the betas for contamination while not being overwhelmed or misled by the gammas.

- Geometry is Critical: To scan large surfaces (floors, tables, hands) quickly, you need a large detection area. thin, lightweight sheets with areas of hundreds of square centimeters are ideal.

2.3. The advantages of scintillator-based surface contamination monitors

- Superior Gamma Rejection: This is the primary reason for choosing certain scintillators (especially ZnS(Ag) coated plastic scintillators). In areas with very high gamma background (e.g., near medical therapy sources, in certain nuclear facilities, or where NORM is present), a standard "pancake" GM or proportional counter can be swamped by gamma pulses, making it difficult or impossible to detect alpha contamination. A ZnS(Ag) scintillator coating in combination with a plastic scintillator base will ignore the gamma and respond only to alpha and beta radiations, providing a clear, unambiguous signal.

- Large size availability: Plastic Scintillators (e.g., PVT) are inexpensive to manufacture in large sheets: You can create large-area floor monitors, portal monitors, or wall monitors for beta/gamma contamination screening at a reasonable cost. These are used at exits from controlled areas ("portal monitors") to quickly scan people or equipment.

- Fast Timing and High Count-Rate Capability:

Scintillators, especially plastic and ZnS, have very fast signal decay times (nanoseconds to microseconds). This means they can handle very high count rates without paralyzing, which is useful in accident scenarios or areas with elevated but acceptable contamination levels.

2.4. Limitations of scintillator-based surface contamination monitors

- Poor discrimination of beta particle from alpha particle: A standard "pancake" gas proportional counter can electronically discriminate between alpha and beta pulses, allowing a single probe to survey for both and provide separate readouts. A monolithic ZnS(Ag) scintillator or plastic scintillator is not capable of simultaneous descriminate alpha and beta. While there is a solution via the “phoswich” design (i.e. combining ZnS(Ag) with plastic scintillator), the phoswich design can lead to problems such as cross-talk and misclassification, where high-energy betas can penetrate to the ZnS coating and be misclassified as alpha; some alpha interactions in the plastic base can be misclassified as beta.

- Susceptible to Light Leakage: All scintillators are light-sensitive. Any breach in the light-tight seal (e.g., a pinhole in the window coating, a cracked light guide) will allow ambient light to flood the PMT.

2.5. Working Principles of scintillator-based Surface Contamination Monitor:

Below is a breakdown of the workflow:

1. Detection of radiation

Place the probe very close to the surface (especially important for α emitters, as α particles have very short ranges in air). Alpha (α) or beta (β) particles emitted from surface contamination strike the scintillator. The detector (e.g. plastic scintillators) captures radioactive particles (α, β, or γ) emitted from the surface.

2. Convert radiation into a signal

Each particle interaction excites the scintillators, producing small flashes of light. A photomultiplier tube (PMT) or photodiode attached to the scintillator converts the light flashes into electrical pulses

3. Signal amplification and processing

Measure the set integration time to achieve statistically stable counts. Background counts are subtracted to get net counts.

4. Results obtained

If net counts or calculated activities exceed the preset threshold, the instrument triggers an audio/visual alarm.

2.6. Specific Scintillator Choices in Surface Contamination Monitors

- ZnS(Ag)-only sensitive to alpha radiations: Can be used in Plutonium handling facilities, High gamma background areas, Uranium enrichment plants, where gamma blindness and detection of weak alpha signals are essential.

- Plasticscintillators (PVT based)-sensitive to beta and gamma radiations: Can be used in Portal monitors (floor, door, hand & foot), where large-area screening, and fast, efficient "gross count” is needed.

- Phoswich (e.g., ZnS+Plastic Scintillator Combination): Combines a thin ZnS(Ag) coating for alpha with a thicker plastic scintillator base for beta. Pulse shape analysis in the PMT can separate the slower ZnS signal from the faster plastic signal, allowing discrimination in a single probe. Hangzhou Shalom EO has developed the SP121 (Equal to EJ444) series plastic scintillators, which are suitable for both α-ray and β-ray detection. The plastic scintillator SP121 consists of a ZnS(Ag) layer coated on the surface of our plastic scintillator SP102 with the ZnS(Ag) layer thickness typically being 4.5mg/cm2.

figure 4. SP121 (Equal to EJ444) series plastic scintillators

3.Fixed Online Dose Rate Monitoring Stations:

3.1. Purpose of Fixed Online Dose Rate Monitoring StationsFixed online dose-rate monitoring stations are permanently installed in nuclear power plants, laboratories, industrial radiation environments, environmental monitoring networks, and any facilities requiring continuous radiation surveillance. They operate automatically, 24/7, to measure ambient gamma dose rate or dose-equivalent rate in real time.

Dose rate is the amount of radiation absorbed or delivered per unit time. Dose rates are often quantified in units of sieverts per hour (Sv/h). You can think this as a person drinks, dose is the total amount of water the person drinks, while dose rate is the speed at which the person drinks water. In some situations, dose rate is important, for example, the risk of exposure to radiation on human bodies can be lower if the same amount of radiation dose is delivered over a long period of time.

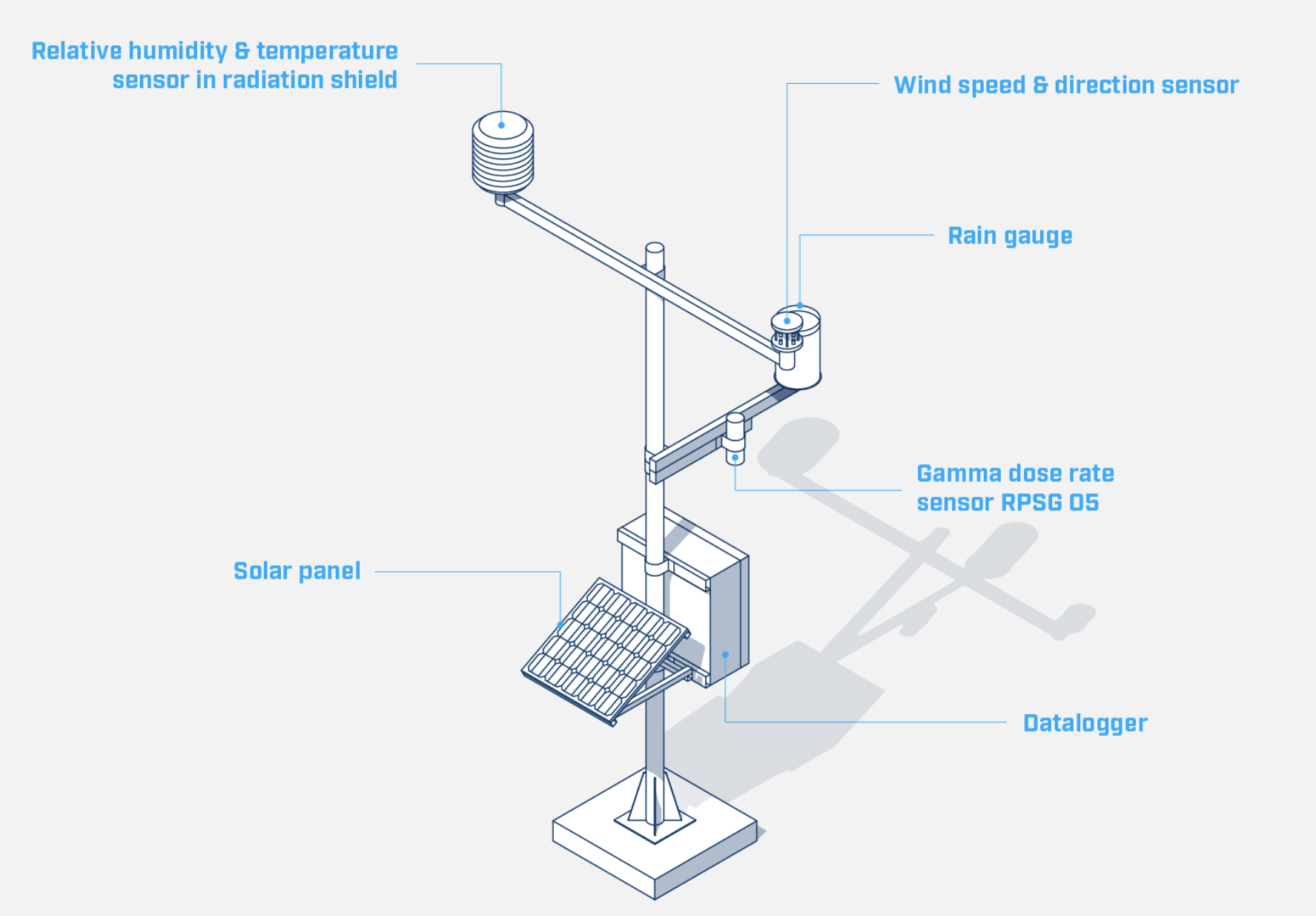

Figure 5. Fixed Online Dose Rate Monitoring Stations

3.2. Challenges Posed for Fixed Online Dose Rate Monitoring

- Wide Dynamic Range and Environmental Stabilities: A fixed monitor must accurately measure dose rates ranging from natural background levels (nSv/h) to potentially very high rates (Sv/h) during incidents or operational peaks. It must maintain calibration and normal operations despite environmental variations such as temperature fluctuations, humidities, dust, and mechanical vibrations over long periods of uninterrupted operation.

- Energy Dependence and Accurate Dose Quantification: The instrument’s response should be as independent as possible of the incident photon or neutron energy to provide a true representation of the ambient dose equivalent (e.g., H*(10)). This requires careful calibration and correction algorithms, especially in mixed radiation fields where the energy spectrum may vary.

3.3. The Advantages of Scintillator-Based Fixed Online Dose Rate Monitors

- High Sensitivity and Fast Response: Scintillators, particularly inorganic crystals like NaI(Tl) or CsI(Tl), offer high light output and excellent gamma detection efficiency. This enables the detection of small increases above background levels with a very short response time (seconds), which is critical for rapid alarm triggering in case of a radiation release.

- Robustness for Continuous Operation: Solid-state scintillation detectors have no moving parts or gas-filled compartments that can leak. They are mechanically robust and well-suited for long-term, 24/7 installation in industrial or outdoor environments when housed in appropriate protective enclosures.

- Capable of NuclideIdentification: Some scintillators materials with high energy resolutions like NaI(Tl) or LaBr3(Ce) provide spectroscopic capabilities. A fixed station equipped with a spectrometer can not only measure dose rate but also perform basic nuclide identification, adding valuable diagnostic information during an event.

3.4. Limitations of Scintillator-Based Fixed Online Dose Rate Monitors

- Temperature Sensitiveness: The light output and resolution of many scintillators, especially organic plastics and some crystals, are sensitive to temperature changes. This can drift the calibration of the dose rate measurement if not actively compensated for with temperature sensors and correction software.

- Limited neutron sensitiveness(for standard gamma scintillators): Standard gamma-sensitive scintillators like NaI(Tl) or plastic are largely insensitive to neutrons. Monitoring neutron dose rates requires specialized scintillators (e.g., LiI(Eu), CLYC) or separate neutron detectors (e.g., He-3 tubes), adding to system complexity and cost for mixed-field applications.

- Potential for Saturation at Very High Dose Rates: In extreme radiation fields, the high interaction rate can lead to pulse pile-up and saturation of the photodetector and electronics, causing the reported dose rate to plateau or become inaccurate. Systems require special high-dose-rate design considerations.

3.5. Working Principles of Scintillator-Based Fixed Online Dose Rate Monitors

Below is a breakdown of the workflow:

1. Continuous Detection of Radiation: The scintillator detector, housed in a weatherproof and often environmentally characterized enclosure, is continuously exposed to the ambient radiation field. Gamma photons (or neutrons, with appropriate scintillators) interact with the scintillator.

2. Conversion of Radiation into an Electrical Signal: The scintillator emits flashes of light proportional to the deposited energies. A photomultiplier tube (PMT) or silicon photomultiplier (SiPM) converts these light pulses into electrical charge pulses.

3. Signal Processing and Dose Rate Calculation: The electronics measure the pulse count rate or the pulse height spectrum. Using pre-programmed calibration coefficients (converting counts per second to microsieverts per hour) to compute the real-time ambient dose rate.

4. Data Output and Alarm Generation: The calculated dose rate is continuously transmitted to a central control room via wired or wireless networks. If the dose rate exceeds user-defined warning or alarm thresholds, the station triggers local and/or remote audible/visual alarms. All data is typically logged for historical analysis and reporting.

3.6. Specific Scintillator Choices in Fixed Online Dose Rate Monitors

- Plastic Scintillators (PVT-based): Chosen for Perimeter Monitoring and High Dose Rate Areas. Their fast timing, low cost for large volumes, and resistance to damage make them ideal for wide-area coverage and environments where very high dose rates might be encountered.

- Inorganic Scintillators (NaI(Tl), CsI(Tl)): Used in General Area Monitoring and Spectroscopes. Their high density and light output provide excellent sensitiveness for low-dose-rate monitoring. NaI(Tl) is the standard choice for applications that require basic gamma spectrometry alongside dose rate measurement.

- GOS ceramics: GOS ceramics (GOS(Pr) and GOS(Tb)) are best suited for fixed online monitoring stations where extremely high sensitiveness, cost-effectiveness, and environmental control are required (e.g., laboratory environments, monitoring of specific high-precision areas). However, in general scenarios requiring large-scale deployment, high cost-effectiveness, strong environmental robustness, or radionuclide identification capabilities, plastic scintillators (PVT) or NaI(Tl) crystals are usually more mainstream and practical choices.

Tags: Scintillator